AГЛИЙСКИЙ. Пособие по английскому языку для машиностроительных вузов допущено Министерством высшего и среднего

Скачать 1.36 Mb. Скачать 1.36 Mb.

|

|

CHAPTER III MACHINE PARTS MACHINE PARTS

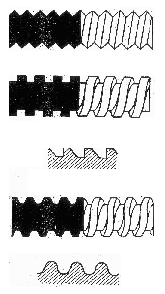

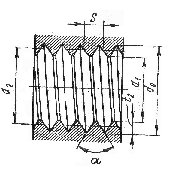

Welding is a process which providers a non-detachable joining of two like metal pieces1 by heating them till melting condition or fusion without or with mechanical pressure. Fusion of two metal pieces may be brought about2 by different types of welding, such as hummer welding, thermit welding, electric welding and gas welding. Hammer welding is a process in which two metal pieces are joined and fused together by force from a hand or power hammer after having heated these pieces in a blacksmith's forge until they reached their plastic stage. Thermit welding is a process consisting of a chemical reaction obtained by igniting finely divided aluminium and iron oxide. This type of welding is used in repairing rails, frames, etc. Electric resistance welding is a process consisting of heating metals to be welded to their plastic temperature and then applying mechanical pressure for achieving a non-detachable joining of the metals. Resistance welding processes form a group consisting of many types of welding. Selection of each type of welding depends on the kind and size of metals to be welded. Resistance welding embraces such processes as spot welding, butt welding, electric arc welding, etc. Spot welding is a process in which two metals are held between electrodes passing a heavy current through the metals to be welded. The electrodes having  Fig. 32. Electric Arc Welding: Fig. 32. Electric Arc Welding:1 — carbon electrode; 2 — additive; 3 — plate; 4 — weld been forced together by pressure join the surfaces of the metals in aspot, the size of which is about the same as that of the tip of the electrode. This kind of welding is suitable for welding parts of airplanes, refrigerators and automobiles. In butt welding the parts to be welded are pressed together while heat is generated by passing a heavy current through the area of the joint. Butt welding may be applied for welding pipes, tubing, rods, etc. Electric arc welding is a process in which surfaces to be joined are fused together by the heat of an electric arc. The electric arc was invented in 1802 by the famous Russian scientist V. V. Petrov, who demonstrated the possibility of utilizing its heat for fusing metals. Fig. 32 shows the process of electric arc welding. By bringing the work and the electrode together as conductors, an electric circuit is established. When the conductors are separated, an electric arc is created in which the electrical energy is converted into heat, its temperature being as high as 7000°F.3 An additive is placed into the flame of the electrical arc. An additive is a metal which is externally applied to the place of welding and melted to form a weld together with the material of the work. The electric, arc melts both the edges of the parts to be melted and the additive used. The electrode having been removed from the place of welding, the molten metal cools, solidifies and forms a weld, joining the parts of the work. In autogenous (gas) welding the source of heat is the gas flame obtained from a gas which is often acetylene. Acetylene mixed with oxygen in a torch when ignited gives a steady flame. The welding torch consists essentially of a gas mixing chamber and is designed in two types: the low-pressure injector type and the equal-pressure type. In the injector-type torch the acetylene is delivered at very low pressure and the oxygen enters the torch at high pressure and velocity expanding in the mixing chamber. Then the acetylene is drawn by suction created in the mixing chamber in a constant ratio to the oxygen. Autogenous welding is carried out in different ways and methods. According to the movement of the torch, welding may be divided into rightward welding and leftward welding: In rightward welding the torch moves ahead of the additive, and in leftward welding the additive moves in front of the torch. In practice rightward welding is mostly used. Gas welding may be used for cutting metals and repairing agricultural machines and implements. ____________________ 1. two like metal pieces — два однородных куска металла 2. fusion of two metal pieces may be brought about — сплавление двух кусков металла может быть произведено (выполнено) 3. 7000°F=7000 degrees according to Fahrenheit — 7000 градусов по Фаренгейту Exercises I. Use the following words and phrases in sentences of your own: electrode, to weld, fusion, non-detachable joining, electric resistance welding, to ignite, iron oxide, arc welding, spot welding, torch, velocity, autogenous welding, to generate, current II. Answer the following questions: 1. What is welding and what is it used for? 2. What types of welding do you know? 3. What is the source of heat for arc welding? 4. What is the source of heat for gas welding? 5. What gas is used in autogenous welding? 6. What methods of autogenous welding do you know? 7. What is spot welding? 8. What is butt welding used for? 9. What is hammer welding? 10. What does the selection of a given type of welding depend on? 11. What processes does resistance welding embrace? III. Supply synonyms for the following words: burner, to fuse, various, to get, to convert, ahead of, to utilize IV. Underline the suffixes in the following words and state what part of speech they belong to: detachable, fusion, mechanical, pressure, obtained, finely, resistance, molten, rightward, agricultural, implement, suitable, possibility V. Give derivatives from the following words and translate them into Russian: to obtain, chemistry, final, to achieve, to conduct, electrical, external, press, wide VI. Change the following sentences using the subordinate clauses instead of participle and gerundial constructions and translate the following sentences into Russian: Example: 1.Having fused two metal pieces we obtained a weld. When we have fused two metal pieces we obtained a weld. 2. We heard of their having applied a new kind of additive to obtain firm joining. We heard that they have applied a new kind of additive to obtain firm joining. 1. After having heated two metal pieces in a blacksmith's forge they reached their plastic stage. 2. Having heated the additive to its melting temperature it began to diffuse into lithe metals to be joined. 3. We heard of their having applied thermit welding to provide a non-detachable joining of two like metal pieces. 4. The engineer informed them of the hammer welding of two metal pieces having been completed. 5. We know of Petrov's having invented the electric arc. 6. Having been asked to join these rods by butt welding, I had to prepare my instruments for this work. 7. Having f found a new method of welding, we were able to join machine parts better and faster. VII. Give English equivalents of the following words: сварка встык, контактная сварка, термитная сварка, сплавлять, шов, соединение, выбор, электрод, ток, площадь, присадочный материал, зажигать, ремонтировать, газосмешивающая камера, затвердевать, остывать, скорость, пламя VIII. Giving answers to the following questions describe the process of electric arc welding shown in Fig. 32: 1. What process is shown in Fig. 32? 2. How can an electric circuit be established in electric arc welding? 3. When is an electric arc created? 4. Where is the electrical energy: converted into heat? 5. What is an additive? 6. Where is an additive to be placed? 7. What is melted by the electric arc? 8. When does the molten metal cool, solidify and form a weld, joining the parts of the work? 2. INDUCTION BRAZING AND SOLDERING Brazing and soldering is a method of joining metals by applying a filler metal of low melting temperature-between the metals to be joined. When the filler metal melts it slightly diffuses into the base metals thus holding the parts together. Soldering is divided into two classifications: soft and hard. In soft soldering filler metals with low melting temperature are used, while in hard soldering the melting temperature of filler metals is comparatively high. In recent years, many complex forgings and stampings have been re-designed to allow fabrication by brazing or soldering of parts produced by mass-production techniques.1 Such new designs have often resulted in striking reductions in cost.2 In other instances, brazing and soldering have permitted the construction of assemblies too costly or complex to be produced by other techniques/Induction heating has proved to have been a valuable aid in these joining processes for many reasons. Among these are rapid heating and precise heat control. The former offers the possibility of localized heating for joining high-strength components with minimum loss of strength. The latter permits sequential brazing or soldering operations to have been performed effectively. Rapid heating also minimizes discolouration and thus facilitates cleaning. Uniform joints with smooth fillets, obtained by induction soldering and brazing, decrease alloy consumption and produce parts which are identical in appearance.3 Frequently, induction brazing and soldering permit a reduction in the required number of holding fixtures. At the same time, the resultant minimum of the fixtures increases their life and maintains their accuracy in alignment of the components to be joined. Basically, brazing and soldering involve fusion of a joining alloy between the surfaces of metal parts to be joined. If the metal surfaces are clean, intimate contact4 is established and the joining material alloys with each surface, forming a joint upon solidification during cooling. The two methods of joining differ primarily in the type and melting temperature of the alloy used to form the joint. In soldering, low-melting-temperature alloys, generally containing lead and tin, permit joints of limited strength to be made at temperatures below 8000 F. Soldering with these alloys is often termed "soft soldering" and is used in fabricating radio condenser cans,5 radiators, terminal strips, instrument cases, etc., and with the metals to be joined consisting of copper and copper alloys such as brass and bronze, carbon and alloy steels, nickel alloys and clad or plated aluminium. Thorough cleaning prior to and during heating is basic for successful soldered joints. Many joint failures may have been traced direitly to poor cleaning and inadequate fluxing. Surfaces to be joned should have been chemically cleaned (freed of heat treatment scale, corrosion products, grease, embedded graphite, etc.) prior to heating, and the joint areas fluxed as soon as possible to avoid contamination from handling or exposure. Suitable fluxes prevent oxidation of the joining alloy and metal surfaces to be joined and also dissolve any residual oxides during heating. They improve the wetting characteristics6 of the joining alloy, thus promoting its free flow upon melting. Zinc chloride and ammonium chloride fluxes in paste form are most frequently used in induction soldering, since they are the most active. Unfortunately, these fluxes leave residues which are corrosive, electrically conductive and hygroscopic. Such flux residues must be thoroughly removed. When this is impossible, as in soldering fine electrical assembly units, rosin or activated rosin-type fluxes which leave non-corrosive and electrically non-conductive residues are used. Fluxes for induction soldering are usually used in paste or liquid form. ___________________ 1. mass-production techniques — технические методы серийного производства 2. to result in striking reductions in cost — вызывать резкое снижение стоимости 3. identical in appearance — одинаковые по внешнему виду 4. intimate contact — прочный контакт 5. radio condenser can — корпус радиоконденсатора 6. wetting characteristics — характеристики смачивания Exercises I. Use the following words and phrases in sentences of your own: brazing, soldering, filler metal, to diffuse, soft soldering, hard soldering, to result in, induction brazing, induction heating, cleaning, smooth fillet, flux, paste, liquid, joint, sequential brazing II. Answer the following questions: 1. What is soldering? 2. How does the filler metal hold the parts together? 3. How may soldering be classified? 4. What kinds of filler metals are used in soft soldering? 5. What kinds of filler metals are used in hard soldering? 6. Why has soldering reduced the cost of production of many assemblies? 7. What type of heating is used in soldering or brazing? 8. What are the advantages of induction brazing or soldering? III. Supply synonyms for the following words: to join, aid, rapid, precise, to decrease, to produce, to improve, clean, melting, clad, promoting IV. Supply antonyms for the following words and translate them into Russian: adequate, cooling, dirty, to decrease, to destroy, low-temperature, conductive, heating, to assemble, fortunately V. Underline the suffixes and prefixes and translate into Russian the following words: redesign, fabrication, induction, non-corrosive, effectively, facilitate, non-conductive, costly, frequently, reduction, basically, discolouration, primarily, successful, failures, hygroscopic, thoroughly, impossible, electrically, conductive VI. Find the predicates in the following sentences, then analyse and translate the sentences into Russian: 1. Recently, techniques have been developed for induction brazing in a reducing atmosphere1 to avoid the use of flux and thus the problems of thorough removal of flux residues. 2. There is a special unit for controlled-atmosphere braz-ing.2 3. In this unit, a purified dry reducing gas, such as hydrogen, enters the unit at the top, displaces the air and surrounds the part to be heated. 4. Upon heating to elevated temperature, oxide films on the metal surfaces to be joined and on the joining alloy are reduced, permitting satisfactory flow of the alloy into the joint by capillary action, thus producing a good bond. _________________________ l. reducing atmosphere — восстановительная газовая среда 2. for controlled-atmosphere brazing — для пайки регулируемой газовой средой VII. Make up questions to which the italicized words are the answers: 1. Soft soldering is used in fabricating radio condenser cans and radiators. 2. Brazing and soldering involve fusion, of joining alloy between the surface of metal parts to be joined. 3. In soldering, low-melting-temperature alloys permit joints of limited strength to be made at temperatures below 800°F. 4. Ultrasonic energy is used in fluxless soldering. 5. Suitable fluxes prevent oxidation of the joining alloy and metal surfaces to be joined. 6. Precise heat control is used to permit effective performance of sequential brazing or soldering operations. VIII. State the forms and functions of infinitives and translate the following sentences: 1. The metals to have been joined included carbon and alloy steels, stainless steel, cast iron, copper and copper alloys, nickel and nickel alloys and, to a limited extent,1 aluminium alloys. 2. The properties of solder may have been changed by addition of some elements such as zinc, aluminum, and phosphorus. 3. A torch should have been used to heat the hard solder and object to be brazed. 4. In order to solder aluminium, flux should be mixed with a special solder used for aluminium. 5. The ternary alloy of silver, copper and phosphorus was largely self-fluxing when used with copper but should have not been used on ferrous metals since it formed a brittle iron phosphide. ______________________ 1. to a limited extent — в ограниченной мере X. Translate the following text in written, form without using a dictionary: It is interesting to note that brazed joints involving cast iron parts are more dependably gas-tight and liquid-tight and have strength if the parts are electrolytically treated to remove graphitic carbon from the joining surfaces before fluxing and induction heating. Fluxes containing fluorides and alkali salts, preferably potassium, are generally used for induction brazing, particularly with the silver-brazing alloys. These fluxes, normally used in paste form, become fluid and active below 1100°F, protecting the metal surfaces to be joined, dissolving residual oxides and promoting better flow of the alloy upon melting. 3. THREADS Threads are applied for interconnection of machine parts and for transmitting motion from one part to another. When a thread is cut on the outside of a part it is known as an "external" or "male thread". A thread is called an "internal'' or "female thread" when cut inside a part. Depending on the shape of the threading tool different profiles of thread are obtained, such as triangular, square or trapezoidal, shown in Fig. 33. In practice triangular threads are most widely used. The main elements of a thread are: the angle of the thread, the major, minor and pitch diameters, the depth and the pitch. These elements are shown in Fig. 33. The angle of a thread is the angle included between the sides of the thread and measured in an axial plane. The major or outside, diameter of a thread d0 (sometimes referred to as "full diameter") is the distance between the two extreme outside points of the thread in the direction square to the axis.1  triangular thread, or V-thread square thread, or flat thread buttress thread trapezoidal thread or acme thread round thread Fig. 33. Profiles of Threads The major diameter is the largest diameter of the thread of a screw or a nut. The minor diameter d1being the smallest diameter of the thread, is the distance between the two extreme inside points of the thread measured at the right angle to the axis. The minor diameter is also called the "core diameter" or "root diameter". The pitch diameter d2is the distance between the two opposite parallel sides of the thread profile perpendicular to the thread axis. The depth t2 of the thread is the distance between the crest and the base of the thread measured normal to the axis, or  Fig. 34. Main Elements of a Thread: Fig. 34. Main Elements of a Thread:d1- minor diameter; d0 - major diameter; d2 - pitch diameter; S – pitch; t2 – depth A crest is the top surface joining the two sides of a thread, while a base of a thread is the bottom surface joining the two adjacent threads. The pitch of a thread is the distance from a point of thread to the corresponding point of the next thread measured parallel to the axis. Screw threads are of both right-hand and left-hand types. In right-hand threads the direction of; the thread is from the right to the left. Right-hand threaded screws are turned clockwise to be screwed into a nut, while left-handed screws  Fig. 35. Screw Thread: Fig. 35. Screw Thread: I — single thread screw;II — double thread screw; III — triple thread screw; a,b, с — pitch should be turned counterclockwise to do that. In screw fastenings threads are made of various shapes, but always of the triangular type, such as: single thread double thread and triple thread (Fig. 35). On the type of the, latter depends the lead of the thread which is the distance a screw thread advances axially in one turn. On a single thread screw the lead and the pitch are the same; on the double thread screw the lead is twice the pitch, while on a triple thread screw the lead is three times the pitch. The most widely used systems of triangular threads in machine-building are: metric, inch and pipe threads. Each thread has its own angle and application. A metric thread profile resembles a triangle with an angle of 60° at its apex. Such a thread is widely used for bolts and nuts. An inch tread profile has an angle of 55°. This type of thread may be used when making spare parts for foreign-made machines. An angle of 55° is also used with pipe threads. Pipe threads are applied for gas and water pipes, as well as for clutches connecting such pipes. ___________________ 1. in the direction square to the axis — в направлении, перпендикулярном к оси |