AГЛИЙСКИЙ. Пособие по английскому языку для машиностроительных вузов допущено Министерством высшего и среднего

Скачать 1.36 Mb. Скачать 1.36 Mb.

|

|

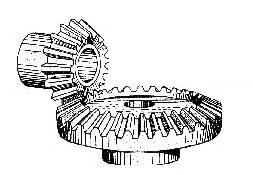

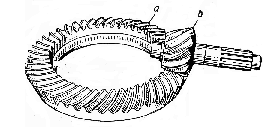

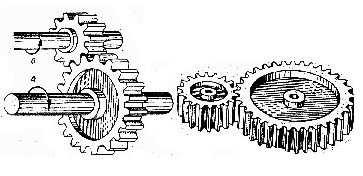

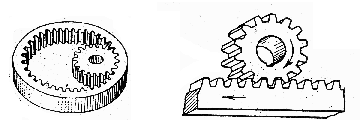

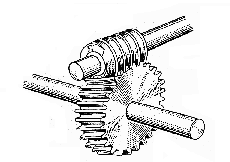

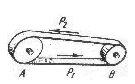

Exercises I. Use the following words and phrases in sentences of your own: round thread, internal thread, triple thread, profiles of thread, triangular thread, square thread, buttress thread, pitch of thread, right-hand thread, screw thread, single thread, left-hand thread II. Retell the text giving answers to the following questions: 1. What are threads used for? 2. What types of threads do you know? 3. What are the main elements of a thread? 4. What types of screw threads do you know? 5. What are the most widely used systems of triangular threads in machine-building? III. Find in the text synonyms of the following words and word combinations: square thread, trapezoidal thread, major diameter, minor diameter, root diameter IV. Analyse and translate the following sentences: 1. The metal cannot be compressed, but is cold forged into a different form, and what takes place when the thread shaped dies are forced into the metal to form a thread is displacement of the surface which is forced into grooves, that is, the material from the depressions forms the elevations on either side. 2. The F-shaped thread must not be made sharp because the sharp crest of the F-thread is very easily broken, and the taps and dies will not stand long due to the sharp thread. 3. The finished thread is of greater diameter than the original diameter of the wire, which in turn is larger than the diameter of the finished thread at the root. 4. A screw or bolt of a given size has a greater minor diameter and a greater strength if the pitch is fine rather than coarse. 5. The finished product is therefore larger in diameter than the blank by an amount approximately equal to the depth of the thread. 6. This process of rolling threads, grooves and screw blanks is used in the manufacture of many articles in preference to cutting the threads or grooves with ordinary slow-cutting tools or threading dies. V. Make up as many questions as possible concerning the following sentences: 1. During the operation the metal is cold forged into a different form. 2. The finished thread is of greater diameter than the original diameter of the wire. 3. A crest of a thread is the top surface joining the two sides of the thread. 4. A base of a thread is the bottom surface joining the two adjacent threads. 5. In screw fastenings threads are made of triangular type. VI. (a) Read and translate the following text using a dictionary: The process of rolling screw threads has been greatly developed and its usefulness extended by the rather recent introduction into common use of a material suitable for roll threading. Iron of ordinary quality does not lend itself well to this process on account of its fibrous structure, which makes this material liable to split or fracture under pressure, but in the modern low-carbon steel we find a material in every way suited to the rapid and economical forming of screw threads. By this process the blank is rolled between two flat dies with their working surfaces grooved to the shape of the thread required these grooves being cut across the face of the dies at the proper angle to suit the pitch and diameter of the screw. (b) Retell the text. VII. On the basis of Fig. 33 describe what profiles of thread are obtained depending on the shape of the threading tool. VIII. Giving answers to the following questions describe the main elements of a thread as shown in Fig. 34: 1. What are the main elements of a thread? 2. What is the angle included between the sides of the thread called? 3. What is the distance between the two extreme outside points of the thread in the direction square to the axis called? 4. What is the largest diameter of a thread called? 5. What is the minor diameter of a thread? 6. What is called the "pitch diameter" of a thread? 7. What is the distance from a point of thread to the corresponding point onthe next thread measured to the axis called? 8. What is the depth of a thread? IX. Describe the shapes of threads in screw fastenings on the basis of Fig. 35. 4. GEARS A gear is a toothed wheel used to transmit rotary motion from one shaft to another. If power is transmitted between the two shafts, the angular velocity ratio of these two shafts is constant and the driving shaft and the driven shaft rotate at a uniform rate. Shafts may be parallel, intersecting, and non-coplanar. Types of gears may be diverse depending upon the above positions of the shafts. Gears may be classified according to their shape and according to the position which the teeth occupy respectively to the axis of rotation. The teeth cut on the face of a gear may be curved, straight or helical. The main types of gears are: bevel gears, eccentric gears, helicalor spiral gears, herringbone gears, screw gears, spur gears and worm gears. Bevel gearing (Fig. 36) is used to transmit power between two shafts, which lie in a common plane and whose axes intersect each other. The axes may be inclined to each other at any angle, although 90° is the most common one. The teeth of bevel, gears may be-either straight or spiral. In the straight bevel gears the elements of teeth converge to a common point called the "apex". Eccentric gears operating on parallel shafts are used to transmit a varying angular velocity either continuously or for a portion of revolution. Helical or spiral gears (Fig. 37) operate on parallel shafts at high speeds, providing maximum strength of gear teeth for a given width of face. Such gears are heat treated and then ground to accurate shape and size, necessary for  Fig. 36. Bevel Gearing Fig. 36. Bevel Gearingsmooth and quiet running at high speeds. The teeth of helical gears, having been cut on a conical surface, curve continually toward or away from the apex of the cone upon which they are cut. These gears closely resemble bevel gears and are frequently called spiral bevel gears. Similarly to helical gears, herringbone gears also operate on parallel shafts. Herringbone gears have helical teeth radiating from the centre of the face towards the sides of the gear body. They are used where high speeds and high gear ratios are necessary.  Fig. 37. Gearing: Fig. 37. Gearing: a — spiral bevel gear, b —hypoid gear Screw gearing is used for converting some rotary motion into a forward motion, and for connecting shafts which are not intersecting. Spur gears are gears having straight or helical teeth cut on a cylindrical surface at an angle to the shaft axis.  Fig. 38. Spur Gearing: Fig. 39. Spur Gear Wheels a — parallel shafts Fig. with External Gearing Spur gearing (Fig. 38) is used to transmit power between two shafts, the axes of which are parallel. Spur gearing may be divided into three types such as: external gearing (Fig. 39), internal gearing (Fig. 40) and rack-and-pinion gearing (Fig. 41). Rack-and-pinion gearing serves for converting rotary motion into forward motion and is widely used in lathes. It consists of a rack-and-pinion.  Fig. 40. Spur Gear Fig. 41. Rack-and-Pinion Gearing Wheels with Internal Gearing  Fig. 42. Worm Gearing Fig. 42. Worm GearingA worm gear (Fig. 42) is a gear having the teeth cut at an angle to the axis of rotation of the gear body and radially in the gear face. A worm gear is driven by a worm which resembles a large screw. Worm gearing is applied for transmitting power between non-intersecting-shafts which are at right angles to each other. In practice friction gearing and toothed gearing are most widely used for transmitting power from one shaft to another and for connecting the shafts. Friction gears are used for light and medium powers in machinery which is frequently started and stopped. Their advantages are flexibility anв noiselessness. The disadvantages of friction gears are the thrust on the bearings and slippage. Toothed gears are used when a constant speed is desirable and the distance between the shafts is rather small. Transmission of notary motion is performed by means of shafts and gears or gear trains mounted on them with the help of inserted keys. Shafts may be of different length and diameters. When rotating, the shafts transmit both the rotation and the torque. Gears replace belt-and-pulley drives where positive motion is required. Gear teeth for all types mentioned above are made in mass production by the generating process on specially designed machines. In this process, the cutter used for cutting teeth has the form of a tooth of the mating gear. One of the most important gear-cutting processes is that of hobbing. In this process, the cutter used for hobbing gear teeth is made like a worm with gashes parallel to the axis to provide cutting edges on the worm. Such a cutter is called the "hob". Exercises I. Use the following words and word combinations in sentencesof your own: a toothed gear, gearing, to hob, to run, to generate, rotary motion, intersecting shafts, spur gearing, bevel gearing, worm gearing, driven shaft, angular velocity, positive motion, inserted key II. Answer the following questions: 1. What is a gear and what is it used for? 2. Where do gears replace belt-and-pulley drives? 3. What types of shaftsdo you know? 4. What do types of gears depend on? 5. According to what features may gears be classified? 6. What kinds of teeth cut on the gear face do you know? 7. What main types of gears can you enumerate? 8. By what processes are gear teeth produced? III. Choose synonymical groups out of the following list: velocity, to transmit, to intersect, smooth, to converge, to transfer, speed, to cross, quiet, to approach IV. Underline the suffixes and prefixes and translate into Russian the following groups of words: controllable, controller, incontrollable; caller, calling, recall; section, sectional; intersect, intersection, non-intersecting IV. Translate the following sentences observing different meanings of the words in italics: 1. When the rain has stopped I noticed a worm on the lawn of our garden. 2. Worm gearing is applied to transmit power between shafts placed at right angles to each other. 3. The Great October Revolution broke out in 1917 and liberated the working class in our country from the yoke of capitalism. 4. Eccentric gears are applied for transmitting a varying angular velocity for a portion of revolution. 5. I locked the door of my flat and left the key on the shelf. 6. Gears fare mounted on shafts by means of keys. V. Find in the text English equivalents of: передача с внешним зацеплением; передача с внутренним зацеплением; винтовая передача; закладная шпонка; прямой зуб; кривой зуб, винтовой зуб, косой зуб, реечная передача, фрикционная передача, цилиндрическое зубчатое колесо, коническое зубчатое колесо, шестерня с косыми или спиральными зубьями, шестерня с шевронными зубьями, вращательное движение, давление, зубчатая передача, червячная передача VII. Make up questions to which the italicized words are the answers: 1. Modern requirements for gears demand that they run quietly at high speeds. 2. Gear-cutting machines have been developed for the rapid mass production of similar parts. 3. The gear blank is pressed on an arbor and held between centres of the dividing head and the index tailstock. 4. Bevel gearing is used to transmit power between two shafts whose axes intersect each other. 5. Spur gearing is used to transmit power between parallel shafts VIII. Using the following words and word combinations describe the bevel gears shown in Figs 36 and 37 and explain the difference between their teeth: bevel gears, to be used, to transmit power, two shafts, axes, to intersect each other, the teeth, to be straight or spiral, Fig. 36, one can see, the straight bevel gears, to converge, a common point, to be called the apex, Fig 37, a spiral bevel gear, to have helical or spiral teeth, to have been cut, a conical surface, to curve toward or away, the apex, helical or spiral gears, to be applied, operation, parallel shafts, high speeds X. Giving answers to the following questions describe the difference between gearings shown in Figs 39 and 40: 1. What types of gearings do you see in Figs 39 and 40? 2. What type of gearing do external and internal gearings belong to? 3. Are the teeth in Figs 39 and 40 straight or helical? 4. How must two shafts be placed when external and internal gearings are used for transmitting power between them? 5. What engagement of two gears does an external gearing provide? 6. What engagement of two gears does an internal gearing provide? X. Look at Figs 38, 41 and 42 and describe in detail the difference between the given gearings. 5. BELT AND CHAIN DRIVES The belt drive is the most widely used kind of driving on metal-cutting lathes. The belt drive in lathes is used mainly for transmitting rotation of an electromotor from one pulley to another owing to the tension of the belt. For instance, in some lathes drive to the headstock is provided by belts from a motor, the mounting plate of which is allowed to pivot freely so that the belts are tensioned by the weight of the motor. The belt-and-pulley system of transmitting rotary motion is subject to belt slippage and is therefore not positive. Belts are still incorporated in the drive, because of the safety factor inherent in a friction drive and because of the silence, as compared with gearing run at high speeds. Fig. 43 shows a belt drive consisting of two pulleys A and В, mounted on two parallel shafts which are connected by an endless belt. The pulley A which transmits rotation is called the "driving pulley",  Fig. 43. Belt Drive Fig. 43. Belt DriveP1,P2— belt tension * while the pulley В receiving rotation from the pulley A and transmitting it to its shaft is known as "driven pulley."** The friction surface of a driving pulley should be of a comparatively soft material, while that of the driven pulley is usually made of hard material. Such an arrangement ensures the maintenance of the friction surfaces. Otherwise, if the driven pulley were made of the softer material, its surface would be injured and ruined. There are two main kinds of belts such as flat belts and V-belts. Flat belts are made of leather, cotton yarn or rubberized cloth. V-belts manufactured of rubberized cloth are of a trapezoidal shape. They are pulled over the pulleys into special grooves, which considerably reduces their slipping off the pulleys during operation. Therefore this kind of belt finds ever increasing application on metal-cutting tools, and is tending to replace flat belts. When a chain is applied there is no rolling contact as with gears. It transmits its tension uniformly to every tooth of the chain gear coming into contact with it. In this case there is no one-tooth action as in gears, and no losses due to rolling friction and the shock of transferring the load from the tooth. The link-belt silent chain can be, and should be, run slack. Belts requirea tension in excess of the effective working tension, and to that extent there is a loss of power on the pulley of the shaft. Belts run on1 by inertia and slip and lose power in that way and the less the belt tension is the more it slips, but the link-belt silent chain never slips. ______________________ 1. Belts run on — ремни набегают Exercises I. Use the following words and phrases in sentences of your own: metal-cutting tools, to pivot, to slip, to lose power, tension of the belt, driven pulley, driving pulley, rubberized cloth, chain gear, slack, to tend, to incorporate, inertia, to ruin, to injure II. Answer the following questions: 1. What is the belt drive used for and in what machines? 2. Because of what feature is the belt-and-pulley system of transmitting rotary motion not positive? 3. Owing to what features are belts still incorporated in the drive? 4. What are the main two types of belts? 5. What are different belts made of? 6. For what purpose are V-belts pulled over the pulleys into special grooves? 7. How does a chain transmit its tension to every tooth of the chain gear which comes into contact with it? 8. What are the advantages of a link-belt silent chain over a belt? III. Underline the suffixes in the following words, and state to what part of speech they belong: tension, pulley, friction, widely, endless, manufacture, special, slipping, effective IV. Connect the following sentences using participle constructions and gerundial constructions: Example: 1.V-belts are of a trapezoidal shape. They are made of rubberized cloth. V-belts made of rubberized cloth are of a trapezoidal shape. 2. V-belts are pulled over the pulleys into special grooves. The special grooves reduce slipping of V-belts. V-belts are pulled over the pulleys into special grooves for reducing slipping of V-belts. 1. The belt drive is used for driving lathes. The belt drive transmits rotation of an electromotor from one pulley to another. 2. The chain transmits tension to every tooth of the chain gear coming into contact with it. The chain is applied on the lathe. 3. The lathe is provided with an electromotor. The electromotor sets in motion the belt drive. 4. The two pulleys of the belt are mounted on two parallel shafts. The shafts are connected by an endless belt. 5. Flat belts are widely used on metal-cutting tools. Flat belts are made of leather or rubberized cloth. 6. The driving pulley is incorporated in the lathe drive. The driving pulley transmits rotation of an electromotor. V. Translate into English: 1. Следует указать, что ремень тем больше проскальзывает, чем слабее его натяжение и чем меньшую часть шкива он охватывает по окружности. 2. Клиновидные ремни натягиваются по нескольку в ряд и укладываются на шкивах в канавки. 3. В токарных станках передачи как клиновидными, так и плоскими ремнями применяются только с натяжным устройством. 4. Передача плоскими ремнями отличается от передачи клиновидными ремнями. 5. Ременная передача в токарных станках применяется главным образом для передачи вращения приводному шкиву от электромотора. I VI. (a) Read and translate the text without using a dictionary: While a motor drive is standard equipment there are certain cases where pulley and belt drive meets the conditions of varied power requirements. It is possible to obtain belt connection with idle pulley and motor mounted in special way. In such a case the 6 inch 6 spindle machine when pulley drive is desired is equipped with 14 inch diameter pulley with (b) On the basis of this text make up questions and answer them: VIII. Giving answers to the following questions describe the principle of operation of the belt drive shown in Fig. 43: 1. What is shown in Fig. 43? 2. How many pulleys does this drive consist of? 3. Where are these two pulleys mounted and how are they connected? 4. What are the functions of the pulleys used in belt drives? 5. How are pulleys classified depending upon the functions performed by them? 6. What pulley is called the "driving pulley"? 7. What pulley is called the "driven pulley"? |