AГЛИЙСКИЙ. Пособие по английскому языку для машиностроительных вузов допущено Министерством высшего и среднего

Скачать 1.36 Mb. Скачать 1.36 Mb.

|

CHAPTER IMACHINE-BUILDING MATERIALS Different metals are widely used in the machine-building industry. Metals applied for industrial purposes are called ''engineering metals". There are two groups of metals: ferrous metals and non-ferrous metals.

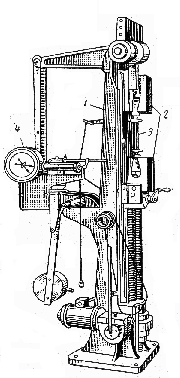

Ferrous metals consist of iron combined with carbon, silicon, phosphorus and other elements. Carbon is the most important of all elements present in ferrous alloys. Ferrous metals are used in industry in two general forms; steel and cast iron, which differ in the quantity of carbon content". These two ferrous alloys are derived from pig iron which is produced in a blast furnace in the form of pigs. Metals are usually melted and poured into a form which is called a "mould". This process is known as casting. The cast metal is shaped in the mould where it cools and solidifies. Thus one can cast different objects known as castings. The shop where metals are cast is called a "foundry". Castings are used in building engines, automobiles and airplanes, and different types of machinery. Steel is iron with a very little carbon content (from 0.05 to 1.7 per cent), which makes it much stronger than iron and is therefore widely used in machine-building. But very much carbon makes steel brittle, which reduces its strength. Therefore the carbon content in steel is confined to certain limits. Cast iron contains a higher percentage of carbon than steel does (more than 2.0 per cent). It is very cheap, in fact, it is the cheapest of all the engineering metals used in machine-building. Grey iron foundries are the most numerous because grey iron can be cast into almost any conceivable shape and size. Grey iron is also adapted to a great variety of castings, such as automobile, gas, steam, and hydraulic engine cylinders, bed plates for machines, car wheels, agricultural machinery parts, furnace and stove parts, water pipes, gears, and general machinery parts. The nature of the metal used for grey iron castings is such that castings can be made so hard that ordinary tool steel will not cut them or, on the other hand, so soft that they can be readily machined. However, in comparison with other casting metals grey iron is weak and will not stand great shock. Hence, the engineer must allow a large factor of safety1 when specifying the use of grey iron castings, especially where great strength is required, or specify that the castings must be made from some other metal. The alloy of grey castings is composed of iron, carbon, silicon, phosphorus, manganese, and sulphur. These elements are used in different proportions depending on the grade of castings. Alloy Grey Iron. In many lines of manufacture and engineering, common grey iron castings have lacked in strength and wearing qualities, so that many experiments have-, been conducted with a view to overcome this shortcoming. This has been accomplished, and the alloy is known as alloy; grey iron, which is easy to machine because most "of the carbon present is in free or uncombined state. It is used much,2 if not entirely, for making steam- and gas-engine cylinders, also for many other castings that require greater strength and wearing qualities than are furnished ,by common grey iron. Alloy grey iron is one of the latest alloys developed and has a promising future. It has a tensile strength of 40,000 to 60,000 lbs. per square inch3 as it comes from the mould, and when it is heat-treated, a much greater strength is produced. Malleable iron1castings are being increasingly used every year in the manufacture of machinery. Many castings that were formerly made of grey cast iron are now made of malleable iron. One of the reasons for using malleable iron instead of grey iron is that malleable iron is much stronger than grey iron castings, particularly in the matter of4 resisting shock. Malleable iron castings can be made muck thinner in section. However^ they are seldom 'used in the form they come from the moulds, as they are hard and brittle, and therefore they should be annealed. Malleable iron before annealing is usually spoken of as white iron. White iron is difficult to machine because most of the carbon present is in chemical combination with the iron. Malleable iron can be cast into very large bodies on account of its high shrinkage and because of the difficulty of annealing. It is the most easily machined of all ferrous alloys. It has to be melted very hot and poured very rapidly, because it solidifies quickly. Malleable iron castings are used in agricultural machinery, railroad equipment, automobile parts, and many other products. The metal is usually tested for tensile strength and elongation. The tensile strength ranges from 38,000 to 55,000 lbs. per square inch and the elongation is usually about 20 to 25 per cent. ______________________ 1. a large factor of safety — большой коэффициент безопасности 2. it is used much — он широко используется 3. lb. per square inch — фунт на квадратный дюйм 4. in the matter of — в отношении Exercises I. Use the following words and phrases in sentences of your own: ferrous metals, steel, cast iron, mould, alloy, pig iron, blast furnace, grey iron, to solidify, foundry, to cast, engineering metals, tool steel, to machine, alloy grey iron, to furnish, malleable iron, to anneal, tensile strength, non-ferrous metals, on account of, grade, to elongate, range, II. Answer, the following questions: 1. What are the main two groups of metals? 2. What elements do ferrous metals consist of? 3. What is the difference between iron and steel? 4. What is casting? 5. What Ho we call the shop where metals are cast? 6. Why is steel widely used, in machine-building? 7. What are the main types of iron castings? III. State the forms and functions of the ing-forms and translate the following sentences into Russian: 1. Machine-building industry is the leading branch of heavy industry. 2. The work of casting metals is performed in foundries. 3. Metals consisting of iron with some other elements are known as ferrous metals. 4. Engineering metals are used in industry in the form of alloys because the properties of alloys are much better than those of pure metals. 5. Steel is iron containing from 0.05 to 1.7 per cent carbon. 6. The blast furnace is called so because a blast of hot air is forced into it while producing the pig iron. 7. Malleable iron before annealing is usually called "white iron". 8. For separating iron from impurities the iron ore must be melted at a very high temperature produced by burning coke in a blast furnace. IV. Fill in the blanks with prepositions because of, of, for, in, with: 1. Metals are ... great importance ... our life ... their useful properties. 2. They are widely used ... industrial purposes. 3. There are two large groups ... metals: simple metals and alloys. 4. Alloys consist ... a simple metal combined ... some other elements. 5. Almost all the metals are found ... the earth's crust ... the form ... ores. V. Translate the following sentences with the predicates in the passive form, then change the predicates into active form: Example: Metals are usually melted and poured by founders into a form which is called a "mould". Founders usually melt and pour metals into a form which is called a "mould". 1. Different metals are produced by people in different ways. 2. Three methods are now used by us for producing pig iron, 3. Ferrous metals are used in industry in two general forms such as steel and cast iron. 4. The iron ore charged into the furnace has been melted by the heat produced by the coke burning in the blast of hot air. 5. Malleable iron castings are being increasingly used in industry. 6. Great shock will not be stood by grey iron. 7. The heat in the electric furnace was produced by electricity. VI. Find in the text nouns for the following verbs: to cast, to alloy, to anneal, to compare, to manufacture, о machine, to equip to produce VII. Make up questions to which the italicized words are the answers: 1. Many experiments have been conducted to improve the qualities of grey iron castings. 2. Some castings require great strength and wearing qualities. 3. Malleable iron castings are much stronger than grey iron castings. 4. Malleable iron can be cast into very large bodies. 5. Metals are usually tested for tensile strength and elongation. VI11. Translate the following text in written form using a dictionary: Production of castings made from different metals requires different types of melting furnaces. The cupola furnace is usually used for melting grey iron. The air cupola, and electric furnaces are used to melt the metal for making malleable iron castings. For melting steel, the open-hearth, crucible or electric furnaces are used. Non-ferrous metals are generally melted in crucibles or electric furnaces. The fuels mostly used for melting metals are coke, coal, oil and gas. Besides the different types of furnaces, different kinds of moulding sand are also required for making the moulds for different metals. In many cases, it is necessary as well to treat either the metals: or the castings in some special way before the castings can be used. 2. STEEL Steel is a ferrous material with some carbon content. There are two kinds of steel: carbon and alloy steel. The content of carbon in steel may vary from 0.1 to 1.0 per cent. Carbon steel should contain only iron and carbon without any other alloying elements and is divided into: (1) Machine steel with a low carbon content from 0.05 to 0.15 per cent. (2) Medium carbon steel with a carbon content from 0.15 to 0.60 per cent. (3) Tool steel with a high carbon content from 0.6 to 1.50 per cent. Carbon steels are the most common steels used in industry, their properties depending only on the percentage of carbon they contain. Machine steels are very soft and can be used for making machine parts that do not need strength. Medium carbon steels are better grade and stronger than machine steels. Tool steel may be used for manufacturing toots and Working parts of machines because of its high strength and hardness. Alloy steels are those in which in addition to carbon an alloying element is present in some appreciable quantity. They are divided into special alloy steels and high-speed steels which, in turn, are called "self-hardening steels". Alloying elements of these steels are: nickel, chromium, manganese, molybdenum, tungsten, vanadium, etc. These alloying elements have a definite effect on the characteristic of the steel; nickel increases its strength and hardness; a high percentage of chromium makes steel rust-resistant and in this case it is called "stainless steel". The addition of some tungsten and molybdenum gives heat-resistant steel. Vanadium makes steel corrosion, shock and vibration-resistant. The sand used for making moulds for steel castings differs greatly from that used in other branches of moulding. It must be much more refractory and open grained,1 because the metal is poured at an extremely high temperature and solidifies very rapidly. If the sand is not refractory enough, it will fuse with the metal. The sand being not open grained, the gases will not escape from the mould rapidly enough, and blowholes will be formed in the casting. Many good steel castings are obtained with green sand moulds. Sand moulds are made by shaping the moulding sand around a pattern which is to have the same shape as the finished object, but their size should be a little larger as the steel casting shrinks while cooling. Moulding sand is to be mixed with water in a certain proportion. Many of the: smaller steel castings are used as they come from the moulds, but most of the larger ones have to be annealed to relieve the cooling strains formed when the metal solidifies. Steel can be used for a great variety of castings, and it can be cast into very large bodies. Cast steel parts enter into the make-up2 of railroad equipment, agricultural machinery, and many other products where great strength is required. The tensile strength of steel castings is from 55,000 to 70,000 lbs. per square inch. Alloy steel castings are coming into more general use with each year, and they are influencing the manufacturing methods. It has been found possible to cast with this alloy some shapes that formerly were necessarily made in other ways. It is used in castings where the greatest strength is needed. Much research is being done to improve not only its strength, but also its wearing qualities. Castings are now produced that have a tensile strength from 70,000 to 150,000 lbs. per square inch, the strength depending upon the composition of the alloy and the method of heat treatment. ________________________________ 1. It must be much more refractory and open grained — он должен быть еще более огнестойким и крупнозернистым 2. make-up — состав Exercises I. Use the following words and phrases in sentences of your own: to rust, alloying elements, to resist, to escape, stainless steel, carbon steel, machine steel, alloy steel, to fuse, corrosion, refractory, rust-resistant steel, heat-resistant steel, green sand moulds, pattern, strain II. Answer the following questions: 1. What is steel? 2. What are the main types of steel depending on the carbon content? 3. What steels are most widely used in industry? 4. What manufacturing purposes may tool steel be used for? 5. What is alloy steel? 6. What alloying elements can change the properties of alloy steel? 7. What sand is used for making steel castings? 8. Why must the pattern be a little larger than the casting which is to be produced? 9. What does the tensile: strength of steel depend on? III. Find in the text verbs for the following nouns: division, casting, difference, fusion, solidification, improvement, requirement, production IV. Translate the following sentences into Russian and observe the different ways of expressing obligation: 1. Steel has to be widely used in machine-building because of its high strength. 2. Alloy steel must be made by adding some alloying elements. 3. Tools made of high-speed steel may do the work at much higher speeds than carbon tool steels. 4. Chromium and tungsten are to increase the hardness and strength of steel. 5. High carbon steel should be hardened by-beating it to a certain temperature and then quickly cooling in water. 6. Special alloy steels can be used for parts requiring great wear resistance. V. Connect the following sentences using Absolute Participle Constructions and translate the sentences into Russian: Example: 1. Steel is one of the strongest metals. We use steel for products where great strength f is required. Steel being one of the strongest metals, we use it for; products where great strength is required. — Так как сталь является одним из самых прочных металлов, мы используем ее для производства изделий, которые требуют большую прочность. 2. Alloying elements for making steel are nickel, chromium, manganese, etc. Nickel increases strength and hardness of the steel. Alloying elements for making steel are nickel, chromium, manganese, nickel increasingstrength and hardness of the steel. — Сплавляе- мыми элементами производства стали являются никель, хром, магнезии и другие, причем никель увеличивает прочность и твер- дость стали. 1. Alloy steels are ever wider used in industry. Manufacturing methods are changed. 2. The metal is poured at an extremely high temperature. The sand-used for making moulds for steel castings should be refractory. 3. Steel is a very strong material. We find wide application of steel in engineering. 4. Heat-resistant steel is made by adding some tungsten and molybdenum. Manganese increases the wear resistance. 5. Steel and cast iron differ in carbon content. The carbon content of steel is little, while that of cast iron is much greater. 6. Some alloying elements make steel rust-resistant. Such steels are called stainless steels. VI. Underline the suffixes and translate into Russian the following groups of words: strong, strength; addition; appreciable, appreciation; define, definite, definition; form, formation, former, formerly; -vibrate, vibration, vibrator, vibratory VII. (a) Read and translate the following text without using a dictionary: PRODUCTION OF STEEL Converter steel is made from molten pig iron by forcing a blast of cold air under great pressure through the metal. The converter represents a large tank made of steel and covered with refractory bricks with an open top through which the molten metal is poured into the converter and out of it. When forcing the blast of cold air through the melted metal, the oxygen contained in the air combines with the carbon of the pig iron, and almost all the carbon in the metal is burned out. Steel made by this method is very cheap, but it is low grade steel because this method of producing steel cannot be well controlled. ; Steel made in this way is called "Bessemer steel". One ton of such steel can be made in one minute, (b) On the basis of the text make up three questions and answer them.

Non-ferrous metals are more expensive than ferrous metals and are used only when some characteristic not possessed by iron of steer is essential or desirable in application. These characteristics are: high electrical "and thermal conductivity, high corrosion resistance, non-magnetic qualities, light weight, etc. The metals most frequently used to make non-ferrous metal castings are copper, tin, zinc, lead, nickel, gold and aluminium. Some of the basic non-ferrous metals and their characteristics are described below. Copper is a reddish-brown, tough metal. It has very high electric conductivity and high corrosion-resistant qualities. Copper is used for making electrical contacts and wires, pipes, telephone Cables, tanks, water heaters, etc. Zincis a hard, brittle, bluish-white metal that is employed in the pure form as sheet zinc. Lead is a very heavy bluish-grey metal/which is very soft. This metal is highly resistant to corrosion, but its strength is so low that it must be supported by a core of some other metal. Lead is used for lining pipes, acid tanks and coating electrical cables. Aluminium is a soft, silvery white metal. It is light in weight, has high corrosion-resistant qualities and is used for automobile and airplane parts as well as for making different light-weight objects used in everyday life such as: frames, cooking utensils, chairs, etc. Tin is a silvery, corrosion-resistant metal. Tin is hardly used in pure form, but is employed as an alloying element. Nickel is a hard, tough, silvery metal. It has high corrosion-resistant qualities and is used for plating other metals such as iron or brass. There are many applications of non-ferrous metals in the unalloyed state, but in most cases, some alloying element is added. The above-mentioned non-ferrous metals may be mixed in various proportions to form many alloys, chief among them being brasses, bronzes, and aluminium alloys. There is a wide range of use for non-ferrous alloys. Their nature differs greatly from that of the ferrous group. By varying the proportions of non-ferrous metals, alloys that are hard or soft, weak or strong, can be produced. When alloying, the metal with the highest melting point should be melted first, then the one with the next highest melting point, and so on until all of the metals that are to make up the alloy are melted together. For example, to make a red-brass alloy, the copper is melted first, then the zinc, then the lead, and at last the tin. As soon as the mixture is hot enough to run the castings, it should be taken out of the furnace, otherwise the zinc, tin and lead may burn away. Brasses are yellowish or reddish alloys of copper and zinc in different proportions (about 60 per cent copper and 40 per cent zinc, but some brasses contain as high as 90 реr cent copper with only 10 per cent zinc). An addition, of tin makes brasses stronger. Brasses are very ductile and may be treated without heating them. They are corrosion-resistant and are used for making musical instruments, bearings, Bronze is an alloy containing primarily copper and tin, but other elements may be added to the alloy to increase ' its properties such as hardness and resistance to wear. The most common bronzes are known as straight bronze, phosphor bronze, and manganese bronze. Straight bronze is usually a mixture of copper and tin, but there are many bronzes that contain zinc and lead, especially the cheap mixtures. phosphor bronze may be made by adding a little phosphorus to the mixture. If phosphor tin is used and alloyed with the copper, better results will be obtained than if the phosphorus is mixed with the copper. Manganese bronze alloys are usually made by using both copper that contains from 5 to 15 per cent of manganese and copper that contains no manganese. Aluminium Alloys. Aluminium is used extensively for castings that are; to be light in weight, light in colour, or that must not rust. Since aluminium is too soft for making castings, it is necessary to mix some other metals with it. The metals that alloy freely with aluminium are copper, zinc, and iron. Usually, where aluminium alloys are made, the aluminium predominates. All non-ferrous castings will take a high polish and will not rust so easily as the ferrous metals, a characteristic that makes them especially useful in wet or damp places. Non-ferrous metals are rather expensive and therefore nowadays scientists try to replace them with some ferrous alloys of lower cost possessing the same properties. Exercises I. Use the following words and phrases in sentences of your own: thermal, mixture, copper, coating, non-magnetic quality, tin, sheet zinc, lining, to support, lead, core, brass, bronze II. Retell the text giving answers to the following questions: 1. What ferrous metals do you know? 2. What are the main characteristics of non-ferrous metals? 3. What are the properties of copper and what is it used for? 4. What do you know about lead? 5. What purposes is aluminium used for? 6. What are the properties of other non-ferrous metals? 7. What metals are used for producing non-ferrous castings? 8. What do you know about brasses? 9. What do you know about bronzes? 10. What are the main properties of non-ferrous castings? 11. Why are attempts made to replace non-ferrous metals by ferrous ones? III. State the forms and functions of infinitives and translate the following sentences into Russian: 1. Some metals have to be melted at very high temperatures. 2. To make non-ferrous castings, such metals as zinc, lead, aluminium and others are melted together. 3. To line pipes and electrical cables such metal as lead is used. 4. One must add some tin to make brasses stronger. 5. Very few objects are made of pure tin, but it is used to make bronze, babbit, and other alloy metals. 6. Nickel is used for covering iron and brasses to make them look better. 7. Nickel does not rust and can be polished to a very bright, silvery finish. 8. To increase hardness and strength of cast copper some cold-working operations are performed. IV. Underline the suffixes and prefixes and translate into Russian the following groups of words of the same stem: to conduct, conductor, conductivity; red, reddish; silver, silvery; to possess, possessive, possession; to plate, plating; to alloy, alloying; to resist, resistance, resistant; strong, strength, to strengthen; hard, hardness, to harden, hardening; pure, impure, purity, impurity, to purify, purification V. Translate the following sentences paying attention to the different meanings of the word make: 1. Addition of copper, zinc and iron makes aluminium stronger. 2. The Soviet makes of new cranes are well known all over the world. 3. The foreman makes the learners pay attention to the casting process. VI. Translate the following sentences into English using infinitive constructions. Example: Для того чтобы увеличить производство металла, необходимо применить новые методы его выплавки. То increase the output of metal it; is necessary to apply new methods of smelting. 1. Для того чтобы увеличить прочность бронзы и сопротивление на износ, к ее составу можно добавить, кроме меди и олова, некоторые другие элементы. 2. Фосфорную бронзу можно получить добавлением небольшого количества фосфора к смеси меди и олова. 3. В практике литейного производства цветные металлы стараются заменить более дешевыми ферросплавами, которые обладают такими же свойствами. 4. Алюминий используется для изготовления различных предметов домашнего обихода. 5. Для того чтобы сделать железо коррозие-устойчивым, его можно покрыть никелем. VII. Make up as many questions as possible on the basis of the following sentences: 1. Copper is used for making electrical contacts and wires because of its high electrical conductivity. 2. Aluminium possesses high corrosion-resistant qualities. 3. Non-ferrous castings differ greatly from ferrous ones. 4. Aluminium is extensively used for castings that are to be light in weight. VIII. Translate the following text in written form without using a dictionary: NON-FERROUS METALS The metals most frequently used to make non-ferrous castings are copper, tin, zinc, lead, and aluminium. These non-ferrous metals have better resistance to corrosion than steel and they are usually easier cast and worked. There are many applications of non-ferrous metals and only few manufactures or machines are made that do not require the service of some or other non-ferrous component. For most purposes the pure non-ferrous metals are too soft and other alloying elements have to be added to create particular physical properties as required by each application. For this purpose non-ferrous metals are mixed in various proportion to form different alloys, such as brasses, bronzes and aluminium alloys, which can be strong, weak, hard or soft. Their cost is considerably greater than that of carbon steel but less than of some of the alloy steels. 4. PROPERTIES OF ENGINEERING MATERIALS AND METHODS OF TESTING THEM While using engineering materials in practice we must know their properties because they affect manufacture and application of materials. All engineering materials have definite characteristics which determine their abilities to assume external loads because of which materials change their shape. When a metal is treated or when machine parts and tools are in the process of work1 the metals which they are made of are subjected to the influence of external forces. These forces are called "loads" and may have different characteristics: according to their value they may be small or large; according to the duration and character of their action they may be constant and impact. According to the influence of the loads upon the metal causing different changes of its shape, loads are distinguished as compression, tensile, torsional, Shearing, and bending ones. By testing a metal under a load one can define what mechanical properties it has. In other words, one can determine strength, elasticity, plasticity, hardness and other properties of the metal. In order to have a clear conception2 of the metal properties it is subjected to tests on special: devices and machines. The determination of these properties is made: in the laboratory using a specimen from the metal to be tested. Let us consider some of the mechanical properties of metals, such as: Strength of metals is the property of hard materials to be subjected to the influence of external forces without incurring damage and without changing their shape. The ultimate tensile strength of a material is: that unit stress developed in the material by maximum slowly applied load that the material can resist without rupturing in a tensile test. A stress is the force within a body which resists defor- mation due to an externally applied load. If this load acts upon a surface of unit area, it is called a "unit force", and j the stress resisting it is called a "unit stress". An external force acting upon an elastic material, the material is deformed and the deformation is in proportion to the load. This distortion or deformation is called "strain". Special machines, called "rupture machines", are used to test metals for strength. Fig. 1 shows one of these machines. When testing a specimen, the upper clamp remains fixed and the lower one is-being slowly lowered, thus causing the extension of the specimen. The load upon the specimen may be easily determined at any moment by means of pointer indications on the dial. Elasticity is the ability of a material to change its shape under the influence of external loads and return to its original form upon removal of the loads. All materials are elastic but the range of elasticity varies for different materials. Elasticity is evaluated by means of the modulus of elasticity. The modulus of elasticity is the ratio of the unit stress S to the unit deformation For determining the elasticity of metals a rupture machine may be used. Plasticity is that property of a material when under the influence of loads, specimens of different materials may elongate while their cross-section decreases. Plasticity is the opposite of elasticity. So, plasticity is the ability of material to change its form without breaking under the influence of load and preserve this changed form after removal of the load. For determining the plasticity of metals a rupture machine may be used too. Hardness of material is the property to resist deformation under applied load. Hardness is the most important mechanical property of metals. Hardness may also be defined as the ability of metals to resist penetration of other harder materials or as resistance to wear.  Fig. 1. Rupture. Machine: 1 — stand; 2 — clamps; 3 — specimen to be tested; 4 — dial Exercises I. Use the following words and phrases in sentences of your own: to penetrate, hardness, cross-section, to determine, to evaluate, plasticity, elasticity, to influence, unit stress, engineering materials, property, to subject, load, external forces, to causey impact loads, compression loads, torsional loads, specimen, shearing loads, unit, surface, clamp, bending loads, rupture machine, extension, dial II. Answer the following questions: 1. Why is it necessary to know the properties of engineering materials? 2. To what forces are machine parts subjected in the process of work? 3. How are the loads distinguished according to their influence upon the metal? 4. What are the most important mechanical properties of metal? 5. What, special devices are used for testing mechanical properties? 6. What is stress? 7. What is strain? 8. What is strength of metals? 9. What is elasticity of medals? 10. What is plasticity of metals? III. State the forms and functions of infinities and translate the following sentences: 1. Malleability of a metal is also known as its ability to be deformed permanently under compression |without rupture. 2. To determine properties of a metal special machines are used. 3. Plasticity of a metal makes it safe to use in all types of structures. 4. The materials to be tested are clamped between two clamps on the rupture machine 5. It is common practice to divide metallurgical materials into ferrous and non-ferrous ones. 6. Some, metals possess special properties, one of which is power to conduct electric current. 7. The ability of a material to take deformation without breaking is known as plasticity. 8. Engineering materials have large industrial applications and their mechanical properties to be studied require much attention. _______________________ 1. are in the process of work - обрабатываются 2. to have a clear Conception — иметь ясное представление IV. Fill in the blanks with prepositions to, within, from, into, on, in, of, by means of, per, without, by: 1. The composition … metals and alloys is important ... the effect it has ... their mechanical, electrical, or magnetic properties. 2. Metals can be cast ... various shapes weighing ... a few ounces ... many tons. 3. Their plasticity, or ability to deform ... rupture allows their formation ... a required shape. 4. The strength ... a metal is generally measured ... tensile tests. 5. Tensile strength is expressed ... pounds ... square inch. 6. When a metal is subjected ... stresses exceeding its elastic limit, the crystals of the metal elongate by an action ... (shearing which takes place ... the crystals and between the crystals. 7. One way ... measuring the hardness is to determine the depth ... which a diamond cone or ball will penetrate ... the metal under a given load. V. Make up nouns and adjectives from the following verbs and translate them into Russian: to subject, to differ, to compress, to develop, to determine, to extend, to remove, to evaluate, to break, to deform, to define, to penetrate, to resist, to indicate, to consider VI. Supply synonyms for the following words: force, to call, to treat, to apply, a specimen, hard, small VI. Supply antonyms for the following words: external, constant, tensile, hardness, compression VIII. Make up questions to which the italicized words are the answers: 1. The deformation test of a metal property is performed in a laboratory. 2. By testing a metal one can define its mechanical properties. 3. In some materials, such as stone or iron, the possible elastic deformation may be very small. 4. In some materials, such as lead, plasticity may imply an almost total absence of elasticity, 5. Elasticity is the capacity of the material to resist produced deformations without permanent change of form. IX. Giving answers to the following questions describe the principle of operation of the rupture machine shown in Fig. 1: 1. What is a rupture machine used for? 2. How do the clamps of the rupture machine operate when testing a specimen? 3. By what means is the load upon the specimen under test determined? |