AГЛИЙСКИЙ. Пособие по английскому языку для машиностроительных вузов допущено Министерством высшего и среднего

Скачать 1.36 Mb. Скачать 1.36 Mb.

|

|

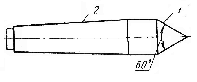

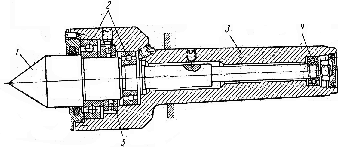

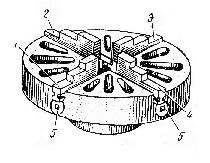

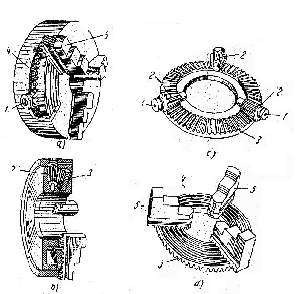

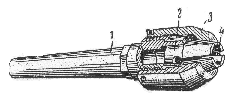

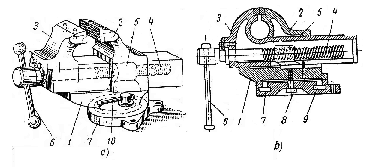

9. METHODS OF HOLDING TOOLS BETWEEN CENTRES When machining a piece of work on a lathe the former is к usually mounted between the lathe centres. Having been mounted on the lathe the work is supported by the conical points of the live and dead centres. The work must therefore have centre holes in each end drilled by using a combined drill -and a countersink. The size of the centre hole has to be pro-a portioned to the weight of the work and the size of cut to be taken. By virtue of the clearance holes the work does notrest on the extreme points of the centres. This is important because otherwise the position of the work will be indefinite. Owing to this method of holding work between centres,the work can be removed from the lathe as often as may bedesired. If the work has to be mounted again between centres for further treatment, it will rotate about the same axis as before. The two lathe centres are mounted in two spindles: one — the live centre is held in the headstock spindle and turns together with the spindle and the work, the other  Fig. 26. Centre: Fig. 26. Centre:1 — cone; 2 — tapered shank — the dead centre is held in the tailstock spindle and: in most cases does not turn and rubs against the work piece. The point of the dead centre should be hardened to prevent its wearing during the operations performed on the lathe. Both lathe centres should always be aligned, i. e. the points are to meet-when the tailstock with its centre is moved up to the headstock centre. A turner tests the alignment of the centres by taking a cut and then measuring both ends of the cut by a micrometer. Having got the same measurements, the turner may be sure that the centres are aligned and he may proceed with the turning. The centre shown in Fig. 26 consists of a cone, on which the work to be treated is installed, and of, a tapered shank, which fits corresponding taper holes in the headstock spindle and tailstock poppet.  Fig. 27. Running Centre: Fig. 27. Running Centre:1 — centre; 2, 4 - ball bearings; 3 - tapered shank; 5 - ball thrust bearing When works are machined at high speeds or when the former are too heavy a dead centre "arid the work will be heated up so as to cause excessive wear from friction. In such cases the so called "running centres" are used. Fig. 27 shows a running centre inserted into the taper hole of the tailstock poppet. The centre rotates on ball bearings. The thrust exerted on the centre is taken by the available ball thrust bearing. The tapered shank fits the taper hole of the tailstock poppet. Exercises I. Use the following words and phrases in sentences of your own to countersink, to mount, live centre, dead centre, head-stock, tailstock, to align, taper hole, to fit, tailstock poppet, running centre, to insert, speed, to exert II. Retell the text giving answers to the following questions: 1. What is the most widely used method of holding work in the lathe? 2. By what parts of the centres is the work supported while being turned? 3. By what means are centre holes drilled in the work? 4. What would happen if the work rested on the extreme points of the centres? 5. Owing to what method of holding work in the lathe, can it be removed from the lathe as often as may be desired? 6. Where are the two lathe centres mounted on the lathe? 7. What kinds of centres are used on lathes? 8. Where is the live centre held and how does it operate? 9. Where is the dead centre held and does it turn or not? III. Underline the suffixes and prefixes and translate into Russian, the following groups of words of the same stem: to combine, combined, combination, uncombined; to lubricate, lubrication, lubricant; to mount, to dismount, mounting, mountable, dismountable IV. Find in the text English equivalents for: зенковка, предотвращать, шпиндель задней бабки, шпиндель передней бабки, вращающийся центр, хвостовик, неподвижный центр, подогревать, центрировать V. Give derivatives from the following words and translate them into Russian: to support, to live, to wear, point, to align, to insert, to fit VI. Change the sentences using the predicates in the Past and Future tenses and translate them into Russian: Example: Each end of the work must be countersunk. Each end of the work had to be countersunk. Each end of the work will have to be countersunk. 1. When being machined the work must be fastened between the lathe centres. 2. Countersinking must be done by means of a countersink. 3. The axial adjustment of the tailstock centre must be done carefully. 4. The poppet must be re-adjusted from time to time during the process of work. 5. The live centre of the lathe can turns together with the spindle and the work. 6. The dead centre of the lathe cannot turn. 7. Both centre points of the lathe must be aligned. VII. Connect the following sentences using participle constructions and translate the sentences into Russian: [ Example: A piece of work has been delivered to the shop. The work was machined on the lathe. Having been delivered to the shop, a work was machined on the lathe. 1. The work has been countersunk with a combined drill and countersink. The work is ready to be machined. 2. The tailstock reduced wear of the dead centre. It has been lubricated. 3. The turner has got different measurements. The turner has to change the position of the dead centre. 4. The worker has turned a special screw in the tailstock. The worker removed the tailstock centre from the tailstock spindle. 5. The point of the dead centre has been hardened. The point of the dead centre increased its wear-resistance. 6. The work has been mounted in the lathe. The work is turned. VIII. Giving answers to thefollowing questions describe the construction and principle of operation of the centre shown in Fig. 26: 1. What parts does the centre consist of? 2. Where is the work to be machined installed? 3. Where does the tapered shank of the centre fit? 4. What causes excessive wear of the dead centre and the work? IX. Describe the construction of the running centre shown in Fig. 27. 10. HOLDING WORK IN A CHUCK Short parts are usually held in a chuck. This method of holding work is of great importance since it is widely used with lathes. A chuck is a rotaing vice which may be attached to the nose of the lathe spindle. There are three important varieties of lathe chucks, such as independent jaw chucks, concentric or self-centering chucks or contracting chucks.  Fig. 28. Independent Four – Jaw Chuck Fig. 28. Independent Four – Jaw Chuck1, 2, 3, 4 – jaws; 5 - screw Fig. 28. shows an independent four-jaw chuck belonging chucks. The chuck has four jaws 1, 2, 3, 4 carried in radial slots in the chuck body. Each jaw of the  Fig. 29. Concentric Chuck: Fig. 29. Concentric Chuck:1 - chuck key; 2 - bevelgears; 3 - large bevel gear; 4 - multi-turn spiralgroove; 5 — jaws chuck can be adjusted independently by means of its own screw 5. It offers the possibility to fasten works of both cylindrical and non-cylindrical shape in such chucks. The body of the chuck is provided with a screwed hole to fit the spindle nose of the lathe. Fig. 29, a shows a concentric chuck. The concentric chuck usually has three jaws which can be moved in and out1 together by means of a chuck key, which is inserted into the opening of one of the three bevel gears (Fig. 29, c) meshed with a large bevel gear (Fig. 29, c). A multi-turn spiral groove (Fig. .29, d) is cut on the flat reverse side, of the large bevel gear. The bottom projections of the jaws are inserted into the separate turns of the groove. When one of the bevel gears is turned by means of the chuck key its motion is transmitted to the large bevel gear. The rotation of that large bevel gear causes simultaneous and uniform motion of all the three jaws along the slots of the chuck by means of the spiral groove. When the gear with the spiral groove is rotated in that or another direction2 the jaws are either approached to or removed from the centre thus clamping or unclamping the work. The concentric or self-centering chuck is very convenient in operation as all its jaws are moved simultaneously. Consequently a work of cylindrical shape is clamped exactly along the spindle axis. This centering is done automatically, therefore such chucks are called "self-centering". The jaws of the chuck are made of hardened and tempered steel to prevent their wear. The chucks are characterized by strong, all-steel construction,3 and are designed to be mounted directly on the spindles of machines without any intermediate plate or adapter thus ensuring utmost accuracy and rigidity. Fig. 30 shows a collet or a contracting chuck. Such chucks are applied for rapid fastening short works of small diameter. The tapered shank of the chuck is inserted into the taper hole of the headstock spindle. A collet with a cone is placed inside the groove  Fig. 30. Collet Chuck or Contracting Chuck; Fig. 30. Collet Chuck or Contracting Chuck;1 - shank; 2 - collet; 3 — nut; 4 — collet opening of the chuck. The work to be treated is set into the hole of the collet. When the nut is screwed on the body of the chuck the collet is contracted and the work gets clamped. Magnetic chucks are adapted to work which is difficult to hold in chuck jaws, either on account of its shape or because the pressure of the jaws may distort the work. The magnetic chucks have no jaws, as the work is held by magnetic force instead of by mechanical means. Some workpieces are so shaped that they cannot be held in a chuck, and work of this kind is often clamped to a faceplate. Most lathes are equipped with two faceplates: one small plate is used for driving workpieces turned between centres, and a large one is used to hold heavy or irregularly shaped pieces. For finishing the external diameter of work which is already bored axially a mandrel, is used. A mandrel is a bar with centre holes at each end. The mandrel is mounted between centres and enables the outside of a workpiece to be turned concentric with the inside and in general such work should have the hole finished first and the outside finished on a mandrel subsequently. The andvantage of mounting work on a mandrel is that of being able to reverse the work on the centres so that the whole of the work exterior can be operated on by cutting tools. ___________________ 1. to move in and out — вдвигать и выдвигать 2. in that or another direction — в том или ином направлении 3. all-steel construction — цельнолитая конструкция Exercises. I. Use the following words and phrases in sentences of your own: chuck, rotating vice, lathe spindle, independent jaw chuck, contracting chuck, chuck body, chuck key, to project, to reverse, motion, to transmit, to mesh, bevel gear, faceplate, mandrel II. Answer the following questions: 1. Where are usually short parts held being turned in a lathe? 2. What is a chuck? 3. What types of chucks, do you know? 4. What purposes are chucks used for? 5. What kind of work are magnetic chucks adapted to? 6.How is the work held in a magnetic chuck? 7. How many faceplates are most lathes equipped with? 8. What kind of work is a mandrel used for? 9. Whatis the advantage of mounting work on a mandrel? III. Supply English equivalents for the following words and word combinations: self-centering chuck, independent jaw chuck, collet chuck,radial slots, groove, spindle nose IV. Find in the text synonyms of the following words: collet chuck, comfortably, with the help of, slot, to revolve V. Give derivatives from the following words and translatethem into Russian: to divide, dependent, possible, cylinder, to open, to transmit, to ensure VI. Read and translate the following text without using a dictionary and analyse the ing-forms and ed-forms: The standard chucks generally furnished are mechanically operated by an automatic mechanism which gives the operator total freedom of both hands for handling the work. While the machine is running to cycle time1 he simply places the work in the chuck which is held there by the work locator2 then he releases the safety foot treadle.3 There are no chucking levers or valves and gauges that require his attention and time. Standard chucks can be furnished with either two three simple jaws and with the jaws contracting or expanding. Chucking pressures are the same at all positions and the pressures are adjustable for different types of work. All standard chucks are constructed entirely of steel having a solid1 steel body, and all the moving parts are made of hardened alloy steel to withstand wear. _____________________ 1. cycle time — цикл хронометрирования 2. work locator— фиксатор 3. safety foot treadle— предохранительная ножная педаль VII. Giving answers to the following questions describe the jaw chuck shown in Fig. 28 and its principle of operation: 1. What kind of chuck is shown in Fig. 28? 2. What group independent four-jaw chuck belong to? 3. How many jaws has the chuck? 4. Where are the four jaws of the chuck situated? 5. How can each jaw of the chuck be adjusted? 6. What possibility is offered by the independent of jaws? 7. What is the body of the chuck provided with? VIII. Using the following words and word combinations describe the construction and principle of operation of the concentric chuck shown in Fig. 29: a concentric chuck, to have three jaws, to move in and out, a chuck key, to be inserted, the opening, one of threemeshed with a large bevel gear, on the flat reserve side, the large bevel gear, a multiturn spiral groove, to be cut, the motion of one of the bevel gears, to be transmitted, by means of the chuck key, to move simultaneously and uniformly, the slots of the body, due to the spiral groove, rotating in that or another direction, the gear with the spiral grooves, to cause, approaching or removing, the jaws of the chuck, from the centre, due to this, the work, to be clamped or unclamped, the advantage, theconcentric or self-centering chuck, in moving all jaws simultaneously X. Describe the construction and principle of operation of shown in Fig. 30. 11. HOLDING WORK IN A VICE Vices are attachments which are mainly used for holding workpieces in machine and fitting shops. It should be noticed that avice may also be used as an attachment for holding workpieces on a metal-cutting lathe. Depending on the character of operation performed bench vices or parallel vices may beapplied. Bench vices are made from forged steel and are of rugged construction. If their construction were not rugged, they could not be used when heavy-duty operations such as cutting, riveting, etc. are performed consists of two jaws: the movable jaw and the solid jaw. At the end of the solid jaw there is a lug for securing the vice to a bench. The extension rod of the jaw is built-in a wooden pillow. When a workpiece is clamped between the jaws they are moved together by means of a square-threaded screw. By unscrewing the screw the jaws are moved apart by a spring riveted to the solid jaw. In parallel vices the jaws move parallel to each other. It should be pointed out that parallel vices in their turn are subdivided into swivel vices and plain vices.  Fig. 31. Swivel Vice: Fig. 31. Swivel Vice: a — front view; b — cross-sectional view; 1 — vice base; 2 —solid jaw, 3— movable jaw; 4 - screw; 5 — fixed nut; 6 — handle; 7 — swivel plate; 8 — spindly 9 — bolt; 10 - lever A swivel vice (Fig. 31), being the most convenient vice in operation, consists of a vice base,* a solid jaw and a movable jaw. The motion of the movable jaw is provided by the; rotation of a screw, inserted into a fixed nut. When the screw is rotated by means,of a handle the former will screw in and move the movable jaw to the workpiece to be clamped. The vice base is mounted on a swivel plate being competed with the latter by a spindle. A bolt is inserted into a T-groove. By turning a handle the bolt may be loosened and the vice may be turned in a desired direction. Plain vices differ entirely from swivel vices in the absence of the swivel plate and that the vice base is bolted directly to a bench. The vice of such a type is made from grey iron, steel hardened plates with a nut being screwed to its jaws. Parallel vices are convenient for clamping workpieces, bull as their jaws are of little strength they are non-suitable for heavy-duty operations. ______________ *American — vice ground Exercises I. Use the following words and phrases in sentences of your own: vices, attachment, bench vice, to rivet, rugged, parallel vices, heavy-duty operation, to secure, movable jaw, solid jaw, lug, pillow, extension rod, swivel vices, plain vices, front view, cross-sectional view, fixed nut, to loosen II. Answer the following questions: 1. What are vices and what purposes are they used for? 2. On what lathes are vices used? 3. Depending on what features may bench or parallel vices be applied for holding workpieces? 4. What material are vices made of? 5. If the construction of the vices were not rugged, could they be used for heavy-duty operations? What main parts does a bench vice consist of? 7. Why is the end of the solid jaw of the bench vice provided with a lug? III. Find in the text English equivalents of: тиски, вид спереди, проекция поворотных тисков в поперечном разрезе, поворотная плита, пружина, основание, завинчивать, неповоротные тиски, тавровый или Т-образный паз, закрепленная гайка, поворачивать, обеспечивать, приспособление IV. Underline the suffixes and prefixes and translate into Russian the following words: attachment, mainly, operation, movable, wooden, convenient, unscrew, disconnect, extension, rugged, performed V. Translate the following sentences, paying attention to different meanings of should and would: 1. It is necessary that all fitting shops should be supplied with bench vices. 2. If the jaws of parallel vices had not been of low strength, the parallel vices would have found greater application in industry 3. It is very important that work-pieces being in the process should be firmly clamped in vices. 4. If fitting shops were not supplied with vices, how would workers clamp workpieces? 5. It is necessary that the vice should be fastened to a bench. 6. Great attention should be paid to the proper securing of the vice to the bench. 7. Providing all the requirements were met, the efficiency of the swivel vices would be increased. 8. If the bolt had been loosened enough, we should have been able to turn the swivelvices in a desired direction. VI. Translate into English: 1. Следовало бы отметить, что неподвижные тиски не очень удобны для работы. 2. Важно, чтобы к губкам тисков привинчивали стальные закаленные пластинки. 3. Необходимо, чтобы на пластинках, привинчиваемых к губкам, была насечка. 4. Следовало бы указать, что параллельные тиски имеют существенный недостаток, заключающийся в малой прочности их губок. 5. Если бы губки параллельных тисков были более прочными, тиски могли бы использоваться для закрепления тяжелых деталей. 6. Если бы крепление стуловых тисков на верстаке обеспечивало надежность их установки, они двигались бы во время работы. VII. (a) Read and translate the text without using a dictionary: Vices are used in tool-rooms and as attachments on metal-cutting lathes for holding workpieces. Vices of rugged construction can hold heavy work, easily withstanding the most severe duty imposed on them. There are different types of vices such as plain vices and swivel vices. The jaws of all the vices are made of accurately ground tool steel. They may be moved, together or apart by means of a handle. The plain vice is used for light milling operations and is fastened to the bench by means of a screw. The swivel vice may be turned through any angle as the base, of the vice is held to the table with a swivel plate. Universal vice may be used for general tool-room work. It can be swivelled up to 90° in the vertical plane and up to 360° in the horizontal plane. (b) Answer the following questions: 1. Where are vices widely used? 2. What do they serve for? 3. What types of vices do you know? 4. What is the difference between plain and swivel vices? 5. By what means are the jaws of all vices moved together or apart? 6. What may the universal vice be used for? VII. Using the following words and word combinations describe theprinciple of operation of the swivel vices shown in Fig. 31: a swivel vice, to be the most convenient vice, to consist, a base, a solid jaw, a movable jaw, the motion, the movable jaw, to be provided, the rotation, a screw inserted, a fixed nut, the screw, to be rotated; a handle, the vice base, to be mounted, a swivel plate, by means of a spindle, to loosen, the bolt, the vice, to be turned in any direction |