AГЛИЙСКИЙ (1). Пособие по английскому языку для машиностроительных вузов допущено Министерством высшего и среднего

Скачать 1.36 Mb. Скачать 1.36 Mb.

|

CHAPTER IIMECHANICAL TOOLS

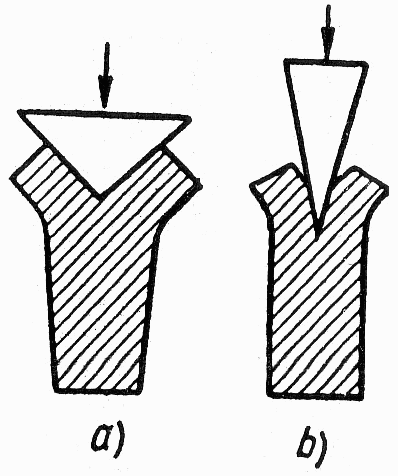

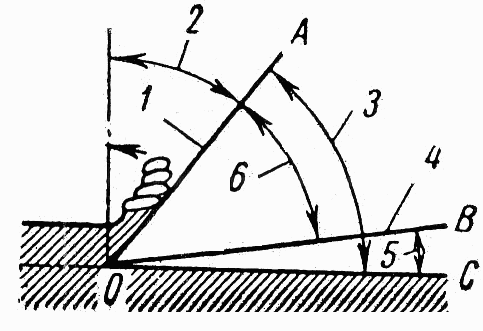

Chipping is a process of removing metal from a workpiece by means of a cutting instrument such as a chisel and a hammer. This process is used when a large piece of metal has to be removed from a workpiece; this process is very labour-consuming1 and is applied only in cases when the workpiece cannot be machined. Chipping is used in cases when it is necessary to cut off a piece of metal from sheet metal. Chipping of large parts is always done on an anvil but very often it is done in a bench vice. The workpiece to be tooled is fixed during the cutting process in the bench vice. There are different tools used in metal-working shops for chipping stocks such as chisels. A chisel is a tool made of very hard steel, having a cutting edge at one end of the blade. This cutting edge is wedge-shaped. Under the effect of an external force applied to the wedge it cuts into the metal. The work of the wedge depends mainly on its cutting angle. The cutting edge of the chisel should be sharpened to an acute angle so as to provide for the best cutting ability, depending on the stock to be chipped. The harder the metal, the larger should be the cutting  Fig. 2. Fig. 2.a — bar with an obtuse angle; b — bar with an acute angle  Fig. 3. Process of Chipping by Means of a Chisel: 1 — front cutting face; 2 — front rake; 3 — cutting angle; 4 — back cutting face; 5 — clearance angle; 6 — lip angle angle of the chisel and vice versa. An angle of about 70° is suitable for most work. Fig. 2 shows a schemeof the process of cutting into metal,and the angles of the wedge. Fig. 3 shows the process of chipping by means of a chisel, as well as the cutting angles. The plane АО called the "front cutting face" or the "top face" is given a backward and sidewise slope for sliding the chips off the tool in a convenient direction while the plane OB is called the "back cutting face". Being formed between the front and back cutting faces of the chisel the angle AOB is known as the lip angle. The angle BOC is the clearance angle which is formed by the back cutting face of the chisel and the surface of the work to be treated. The slope in the direction of the chisel length in which the chip moves is called the "front rake" or "true rake". The angle AOC formed by the lip angle and clearance angle is known as the "cutting angle". There are different types of chisels such as flat chisels, cape chisels, etc. Hammers are striking tools used in chipping, bending and other operations. Hammers are made of a solid piece of forged tool carbon, steel, their weight depending on the stock to be removed. _______________________ 1. labour-consuming - трудоемкий Exercises I. Use the following words and phrases In sentences of your own: to chip, chisel, stock, mechanical tolls, blade, wedge, edge, cutting angle, acute angle, plane, lip angle, clearance angle, cape chisel, front rake, to strike, to forge, solid II. Retell the text giving answers to the following questions: 1. What is chipping? 2. What instruments are used in chipping? 3. What is a chisel? What types of chisels do you know? 4. What does the work of a chisel depend on? 5. What does the angle of the cutting edge of a chisel depend on? 6. Why is the top face of a chisel given a certain slope? 7. What is the front rake? 8. What plane is called the "front cutting face? 9. What plane is called the "back cut- ting face? 10. What is the clearance angle, the lip angle and the cutting angle? III. Fill in the blanks with prepositions by, from, in, of, on: 1. Chisels are used … removing stock … works. 2. Chisels are usually made … a high grade steel. 3. The cutting edge … a chisel is ... the form … a wedge. 4. The correct cutting angle … a chisel depends … the strength …a stock to be chipped. 5. Stocks are chipped ... means … a chisel and hammer. IV. Supply antonyms for: the following words: hard, large, suitable, convenient, backward, long V. Make up adverbs from the following words and translate them into Russian: different, hard, main, external, large, convenient VI. Change the following sentences using the Infinitive Construction and translate them into Russian: Example: The chisels which are to be used for chipping metals are made of high grade steel. The chisels to be used for chipping metals are made of high grade steel. 1. Different types of chisels are made of a good grade chisel steel which has to be forged, annealed, and then hardened and tempered. 2. Chisels which must be applied for chipping metal stocks are made of hard steel. 3. Working a metal to a desired shape by forging produces the best combination of physical characteristics for parts which will be highly stressed. 4. An auxiliary equipment which will be 5* used together with the forging hammer must withstand the vibration or impact of the forging blows. 5. The weight of hammers depends on the stock which will be removed. 6. The work required to separate the chip from the stock will depend upon the material which is to be machined and the separation area. VII. Translate the following sentences, observing different meanings of the words and word combinations given in italics:Pliers, or wire-cutters (Fig. 4) are used for cutting thin 1. There are different means of chipping stocks.2. Chipping is performed by means of such instruments as a chisel and a hammer. 3. It means that you have to remove some more metal from the workpiece. 4. By no means should this chisel be used for this workpiece. 5. A chisel must by all means he applied for removing some metal from the work-piece. VIII: Make up questions to which the italicized words are the answers: 1. The workpiece to be tooled is fixed during the chipping process in the bench vice. 2. A chisel is a tool made of very hard steel. 3. A chisel has a cutting edge at one end of the blade. 4. The cutting edge of a chisel is wedge-shaped. 5. The angle between the two edges of the tool in the plane of the true rake is called the "lip angle". IX. Using the following words and word combinations describe the drawing shown in Fig. 2: a chisel, to be a tool of very hard steel, to have a cutting edge, to be wedge-shaped, to be under the effect of an external force, to cut into metal, the work of the wedge, to depend on the cutting angle, to be sharpened to an acute angle, to provide the best cutting conditions.

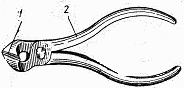

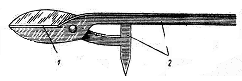

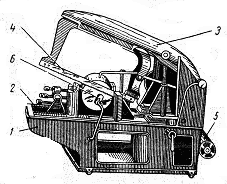

Metal cutting differs from-chipping in substituting impact stresses by pressing forces in this operation. Cutting is used for separating some part from a piece of metal as well as to cut angles, grooves and pipes. Depending upon the shape and size of workpieces cutting is done by means of different cutting tools such as pliers, bench-shears, alligator shears, hack saws and pipe-cutters made of carbon steel.  Fig. 4. Pliers: Fig. 4. Pliers:1 – cutting jaw; 2 – handle Pliers, or wire-cutters (Fig. 4) are used for cutting thin wire. Pliers consist of two cutting jaws and two handles.A piece of wire is placed between the cutting jaws and the wire is cut by exerting pressure on the handles of the pliers.  Fig. 5. Bench-Shears: Fig. 5. Bench-Shears: 1— shear blade; 2 — handle Bench shears are made of steel. Lateral surfaces of shear blades are hardened, sharpened and ground. Bench-shears (Fig. 5) are provided with two handles one of which is at a right angle to the other and fixed on a bench. The length of the handle is 400-800 mm, while that of the cutting part is 100-300 mm. The material is cut by pressing on one of the handles.  Fig. 6 Hack Saw Fig. 6 Hack Saw 1 — frame: 2 — toothed blade A hack saw (Fig. 6) is used for cutting thick metal sheets, bars, round-shaped material, etc. The hack saw consists of a frame and a long toothed blade made of tool carbon steel. The teeth on the blade are hardened. The blades with different pitches have different applications, the pitch of the blade depending on the material to be sawed. The thinner the material to be handled, the finer must be  Fig. 7. Alligator Shears: Fig. 7. Alligator Shears:1 - bed; 2 — bedplate; 3 — arm; 4 — cutting blade; 5 — electromotor; 6 — machine vice the pitch of the blade used for sawing this material, and vice versa. Fig. 7 shows alligator shears which is a heavy duty machine) for cutting materials of large sections such as pipes, beams, auto frames, axles and different types of industrial scrap. The alligator shears consist of cast iron bed 1 and bedplate 2. Arm 3 is mounted on the bedplate. Cutting blade 4 is fixed within the arm. Electromotor 5 imparts reciprocating motion to the arm and the, blade. The workpiece to be cut is clamped in machine vice 6. Special pipe-cutters (Fig. 8) serve for cutting pipes. The pipe-cutter consists of body 1, handle 4, and three steel cutting rollers. Two rollers 2 installed on the fixed axles of the body and roller 3 installed on the axle of the handle may revolve and cut a pipe fixed in a special pipe fixture. For this purpose the pipe-cutter is turned round the pipe to be cut, pressing the cutting rollers against its surface.  Fig. 8. Pipe-Cutters: Fig. 8. Pipe-Cutters:1- body; 2 – rollers; 3 – roller; 4 - handle Exercises I. Use the following words and phrases in sentences of your own: bedplate, arm, pitch, bar, lateral, metal cutting tools, pliers, pipe-cutters, hack saw, cutting jaws, to harden, right angle, bench-shears, to press, bed, industrial scrap, groove, to impart, reciprocating motion, to install, fixture, body II. Supply the missing words: 1. The p… of a blade is the distance from the point of one t… to the point of the next t… .2. This pitch is expressed by the number of t... per one inch of the b… length. 3. The hand hack saw blade is a thin blade with teeth formed on one e… . 4. The flexible h... s... blade is used for s...ing tin, copper, aluminium and other soft metals. 5. Cutting is done by means of different c... t... . 6. For cutting wire such cutting t... as p... are used. 7. One handle of b...-s... is at a r... a... to the other. III. Translate the following sentences into English using the infinitive instead of the attributive clauses: Example: Материал, который нужно разрезать, зажимается в тисках. The metal to be cut is clamped in the vice. 1.Шаг полотна ножовки зависит от материала, который будет распиливаться, 2. Различные виды стали, которые используются для полотна ножовок, изготовляются на нашем заводе. 3. Полотно ножовки, которое надо использовать для распиливания этих тонких листов, должно иметь 32 зуба на один дюйм. 4. Труба, которую надо разрезать труборезом, будет закреплена в специальном приспособлении. 5. При вращении трубореза вокруг изделия, которое надо разрезать, создается режущее усилие. IV. Make up questions to which the italicized words are the answers: 1. This bar is subjected to the action of two sets of external forces. 2. Cutting is used in cases when it is necessary to separate a piece of metal. 3. Thin wire is cut with pliers. 4. Sheets of metal are cut with bench-shears. 5. Cutting tools are made of carbon steel: 6. Pliers consist of two cutting jaws and two handles. V. Giving the answers to the following questions describe the principle of operation of pliers, bench-shears, and alligator shears and pipe-cutter shown in Figs 4, 5, 7, and 8: 1. What are pliers used for? 2. What do the pliers consist of? 3. What is the funtcion of pliers, jaws and handles? 4. What material are bench-shears made of? 5. What are the bench-shears provided with? 6. What purposes are alligator shears used for? 7. What principal parts do the alligator shears consist of? 8. What part of the alligator shears is the arm mounted on? 9. Where is the cutting blade of the alligator shears fixed? 10. What motion does the electromotor impart to the arm and the blade? 11. What purpose are pipe-cutteres used for? 12. What parts does a pipe-cutter: consist of? 13. How is the cutting performed? 14. Where is the-pipe fixed for cutting?

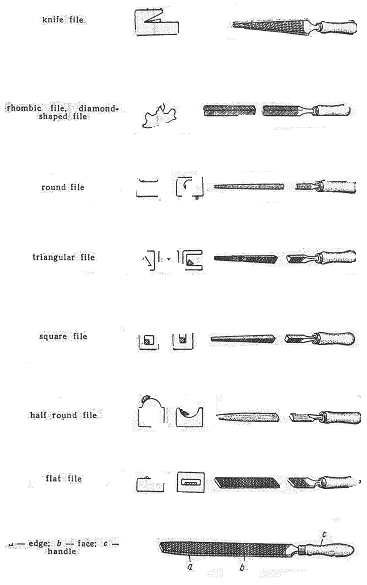

Filing is the most widely used fitting operation in the practice of metalworking shops used for cutting metal by means of a tool known as a file. By means of a file it is possible to give a different shape and size to a workpiece, to fit one part to another, etc. The most widely used operations with a file are: (1) filing separate surfaces, (2) filing mating surfaces, (3) filing holes. A file is a hardened steel bar having a great number of fine cutting edges or teeth running diagonally across its face. These teeth can remove fine chips from a treated work-piece. A file differs from a chisel in having a large number of cutting points instead of one cutting edge and in being driven directly by hand instead of by hammer. There are various kinds of files applied for finishing different workpieces depending on the shape of their surfaces (Fig. 9). Flat files are used for filing flat surfaces but the shape of the files is not quite flat because if the file had been made quite flat, it would have prevented the production of a flat surface, as the file would have cut away at the edges of a work and would have left a convex surface. For filing convex and concave surfaces half-round files are used. A half-round file is made with a convex surface to prevent all the teeth from cutting at the same time, which requires too much pressure on the file, as well as to prevent the file from bending. Square files are applied for filing square holes and rectangle grooves, while triangular or three-square files are used for filing angles. Round files are used for filing round holes of small diameters, and for filing metal in narrow places diamond-shaped files made of copper strip into which diamond powder has been hammered, or knife files are used. For filing soft metals rasp files or rasps are employed.  Fig. 9. Files Fig. 9. FilesExercises I. Use the following words and phrases in sentences of your own: to file, to fit, mating surfaces, face, a great number of, convex surfaces, triangular file, to prevent, strip II. Retell the text giving answers to the following questions: 1. What is filing? 2. What tools are used for filing operations? 3. What operations are performed with a file? 4. What is the difference between a file and a chisel? 5. How is cutting performed with a file? 6. What files are used for filing depending on the shape of the surfaces to be finished? III. Supply antonyms for the following words: flat, convex, soft, different IV. Give the derivatives from the following words and translate them into Russian: to differ, to operate, file, to fit, diagonal, to finish, to separate V. Change the following sentences using the clauses instead of participle, phrases and translate thesentences into Russian: Example: Files with convex surfaces, preventingall their teeth from cutting at the same time, are used for filing convex and concave surfaces. Files with convex surfaces which prevent all their teeth from cutting at the same time are used for filing convex and concave 1. Files are generally made; with convex surfaces being thicker in the middle than at the ends. 2. Files various shapes, of cross-section such as square, flat, round, etc are used in metal-cutting practice. 3. When filing convex surfaces one uses a half-round file. 4. A file is an instrument having teeth on its face. 5. Files are tools belonging to the group of locksmith's cutting instruments. 6. Files having single cut teeth, are called "single-cut files", 7. For removing a large amount of metal one uses a coarse-pitched file. VI. Make up questions to which the italicized words are the answers: 1. A file has a great number of fine cutting teeth. 2. These teeth are used for removing chips from, theworkpiece to be treated. 3. Depending on the shape of the surfaces to be filed various kinds of files are used. 4. No, flat files are not used for filing round holes. Round files are used. 5. No, knife files are not used for filing soft metals, but rasps are 'used. 6. Yes, diamond-shaped files are used for filing metal in narrow places. VII. Giving answers to the following questions describe Fig. 9: 1. What is a file? 2. What principal parts does a file consist of? 3. In what cases is a square file used? 4. Which file is used for filing angles? 5. What material are diamond-shaped files made of? 6. In what eases are knife files used? |