AГЛИЙСКИЙ (1). Пособие по английскому языку для машиностроительных вузов допущено Министерством высшего и среднего

Скачать 1.36 Mb. Скачать 1.36 Mb.

|

|

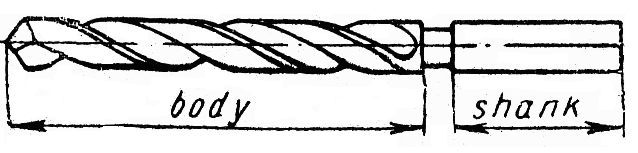

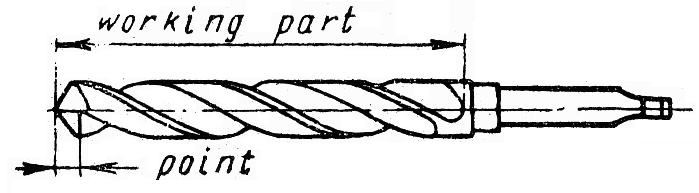

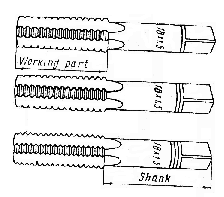

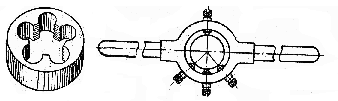

Exercises I. Use the following words and phrases in sentences of your own: to bevel, side tool, facing, roughing tools, to grind, to rough, speed, finishing tool, to provide, to adjust, to set, single-point cutting tools, turning tools, effective cutting edges, tip, shank II. Use these verbs in the past participle form and make up sentences using past participles as attributes: to grind, to turn, to form, to cut, to temper, to harden, to provide III. Underline the suffixes and prefixes and translate into Russian the following group of words of the same stem: to adjust, adjustable, adjusting, adjustment; to continue, continual, continuance, continuation, discontinuation, discontinuance, to discontinue; to divide, divided, division, divisional, divisor, to subdivide, subdivisible, subdivision IV. Choose synonymical groups out of the following list: the sharper, to undergo, to understand, precise, accuracy, to realize, to complete, to start, to subject, to finis, to begin, accurate, to clamp, precision, to squeeze, to grind V. Change the following sentences, using the subordinate clause instead of participle phrases. Translate the sentences into Russian: Example: Cutting tools used for various metal-cutting operations have quite a wide range of shapes. Cutting tools which are used for various metal cutting operations have quite a, wide range of shapes. 1. The number and types of cutting tools used in practice are very large. 2. Tools designed to take heavy roughing cuts are known as roughing tools. 3. Milling cutters have several cutting edges giving the cutter the advantage of cutting. 4. Each blade of the milling cutter is a single-point cutter provided with proper rake and clearance angles. 5. The cutting angle is determined by the physical characteristics of the material being machined. 6. A high cutting speed, a small chip thickness and a large rake angle are factors facilitating the flow of the chip over the face of the tool. 7. Different kinds of cutting tools are used for metal cutting processes depending upon the kind of metal being cut. 8. The elements of a single-point tool used for turning operations are shown in Fig. 20. VI. State the kinds of subordinate clauses in the following sentences and translate them into Russian: 1. The distance that the tool is set into the work for cut-ting operations is referred to as the depth of cut. 2. Metals may be so strong that it is difficult to produce a tool capable of cutting off the chip without frequent failures. 3. If the metal to be cut is soft, the top rake of the tool is decreased. 4. When a tool cuts metal a force is exerted on its face by the material pushed ahead, and a friction force is set up along the face of the tool by a sliding chip. 5. If the tool were not ground correctly, it would not freely. 6. The basic principle of design employed in making single-point cutting tools is the wedge which can be modified in accord- ance with requirements. VII. Translate the following sentences into. English using different ways of expressing obligation: 1. Все резцы, в зависимости от типа машины, на которой они используются, нужно подразделять на токарные, фрезерные, строгальные и другие. 2. Для того чтобы продлить работу режущего инструмента, следует правильно выбирать скорость резания. 3. Угол заточки инструмента должен меняться в зависимости от материала обрабатываемой детали. 4. Инструмент, который нужно затачивать и устанавливать в определенное положение в автоматическом станке, следует насаживать с меньшей силой, чем обдирочный резец. 5. Режущие инструменты могут затачиваться до тех пор, пока не останется маленькая полоска режущей кромки, и все же их можно еще использовать для резки материала. VIII. Give different meanings of the words proper, to make, one, for, above, more, that. Give some examples of their use. IX. Make up questions to which the italicized words are the answers: 1. On solid tools it is necessary to grind the top rake in thetool. 2. To turn cast-iron it is necessary to set the tool above centre. 3. The tool is ground with the slide clearance to prevent the dragging of the tool on the shoulder formed by the cut. 4. If the surface of the work being machined is too great, the cutting edge will be worn too rapidly. 5. Roughing tools are applied for roughing or removing excessive metal from the work. 6. To prevent the breakage of the cutting edge of, a necking tool, the height of the head is made several times larger than the width of the cutting edge. X. (a) Read and translate the following text without using a dictionary: Lathe tools are made of carbon steel, high speed steel and alloys such as stellite and cemented carbide. The stellite and cemented carbide tools are becoming more generally used as their cost is reduced. There are but few carbon steel tools used,1 the general practice is to use high-speed tool bits in holders. One should determine the kind of tool to be ground, as carbon and high-speed steel require different treatment. Tools should be marked to show the kind of material from which they are made. To ensure the proper operation of a lathe the cutting tools should be ground by hand or machine. In machine grinding the tool is supported rigidly in a chuck or holder and ground semi-automatically to the desired rake and relief or clearance angles. In grinding by hand, the tool should be supported oh the work rest and moved back and forth across the entire face of the grinding wheel. The accuracy of a tool ground by hand depends almost entirely on the skill of the operator. __________________ 1. there are but few carbon steel tools used — применяются лишь немногие резцы из углеродистой стали (b) Answer the following questions: 1. What steel are lathe tools made of? 2. Why should one determine the kind of tool to be ground? 3. How should the cutting tools be ground to ensure the proper operation of a lathe? XI. Giving answers to the following questions describe the construction of the cutting tool in Fig. 19 and the angles to which a cutting tool shown in Fig. 20 should be ground, and clamping the tool in a toot holder in Fig. 21: 1. What parts does a cutting tool consist of? 2. What is the shank of the cutting tool used for? 3. What is the synonym for the word "cutting edge"? 4. By what means can the cutting tip of a tool be ground? 5. To what angles-should the tip of the cutting tool be ground? 6. What do the shape of a tool as well as its rake and clearance angles depend upon? 7. How can the top rake be varied? 8. What does the top rake depend on? 9. How does the side rake Vary for soft material and for steel? 10. What does the front clearance depend on? 11. What action would be performed by the tool if it were ground square without any front clearance? 12. Why is the tool ground with a side clearance? 13. How should the tool be clamped in the tool holder before starting the cutting operation? 7. DRILLS AND RILLING Drilling is one of the cutting operations producing cylindrical holes of different diameter in solid material by means of rotating tools called «drills»(Fig. 22). The most common type of drill in use1 is the twist drill made of tempered steel round bar stock. Twist drills are made with two, three, or four spiral grooves or flutes milled from the solid. These grooves or flutes winding around the body of the drill serve for forming the cutting edges of the drill, as well as for removing the chips formed in drilling from the hole.  Straight-Shank Drill  Tapered-Shank Drill Fig. 22. Drills The twist drill comprises three principal parts: body, shank and point. The twist drill has two cutting edges known as the "lips". These cutting edges, or lips, are connected by a third edge, called a "web". It is this part that gives rigidity and strength to the drill. When in" use the first two cutting edges remove the material from the work, while the third one penetrates into the material by rubbing rather than cutting. In order to drill holes in a metal the cutting edges of a drill should be correctly ground to a. certain angle. When a drill is ground correctly, its cutting edges, or lips, should have equal length whereupon each of them should make the same angle with the centre line. Otherwise the drill will make holes the diameter of which is larger than that of the drill. This may disable the drill and cause an undesirable waste of material. Drills have shanks of various types, the most commonly used being those having straight and tapered shanks. The shank of the drill serves for clamping the drill either in the chuck spindle or socket of a drilling machine. The above part of the drill may be either of a cylindrical shape, like in2 straight-shank drills, or of tapered shape in tapered-shank drills. The third part of the drill is called a "drill point". It .is always ground to a cutting angle varying with the kind of material to be drilled. For hard materials this cutting angle equals 140° and for soft materials it equals 90°. The cutting edges of flat drills used for drilling holes in steel or in cast-iron are ground to an angle of 100° to 120°. All the drills get worn while drilling and they should be re-ground from time to time. _____________________ 1. The most common type of drill in use - самым обычным используемым типом сверла... 2. like in — как в, подобно Exercises I. Use the following words and phrases in sentences of your own: to drill, cylindrical holes, rotating tool, twist drill, slute, to mill, lips, web, spiral grooves, tapered shank, focket II. Retell the text giving answers to the following questions: 1. What is drilling, and its purpose? 2. By means of what tools is drilling performed? 3. Which is the most widely used tool for-drilling? 4. What material is a twist drill made of? 5. What purposes do twist drill flutes serve? 6. What are the principal parts of a twist drill? 7. What are the cut-1 ting edges of a twist drill called? 8. What part of the twist drill gives it rigidity and strength? 9. Why should the cutting edges of a drill be correctly ground? 10. Why should the cutting edges of a drill have an equal, length? III. Form adverbs from the following adjectives: proper, cylindrical, certain, good, wide, correct, equal IV. Underline the suffixes and prefixes and translate into Russian the following groups of words of the same stem: to desire, desirable, undesirable; cylinder, cylindrical, cylindrically; to straighten, straight; to grind, ground, re-ground; equal, equality, equalization, to equalize, equalizer, unequal, unequalled V. Supply the missing words: 1. In drilling h... in metal, heavy pressure must be applied at the drill p… . 2. Spiral f... are found on most drills. 3. The c... angle at the outer corner of the l... should be about 12°. 4. The cutting edges of t... d... have angles of top rake and clearance the same as any other c... t... have. 5. The body of metal between the flutes forms what is called the w... . 6. The drills are held in place by their t... shanks or by gripping straight-s... drills in a c... . VI. Connect the following sentences using the conjunction either... or: Example: The body of the twist drill has two spiral grooves. The body of the twist drill has, flutes cut on its surface. The body of the twist drill has either two spiral grooves or flutes cut on its surface. 1. The-twist drill is formed by twisting grooves in a flat piece of steel. The twist drill is formed by milling a cylindrical piece of steel. 2. The grooves serve to form cutting edges of the drill. The grooves serve to remove the chips, formed in the process of drilling. 4. The drill flutes serve to lubricate the drill. The drill flutes serve to remove chips from a hole being drilled. 5. The work to be drilled should be clamped in a vice. The work to be drilled should be clamped in a chuck. 6. The web of a drill penetrates into thе material being cut. The web of a drill rubs the material. VII. Translate the following sentences into English using the past participle instead of the attributive clauses: Example: Часть сверла, которая называется режущей частью, всегда затачивается под определенным углом резания. The part of the drill called a "drill point" is always ground to a certain cutting angle. 1. Операция, которая выполняется при помощи инструмента, называемого «сверлом», называется «сверлением». 2. Стружки, которые образуются при сверлении, удаляются по канавкам сверла. 3. Режущие кромки сверла, которые используются для сверления, должны затачиваться под определенным углом. 4. Инструмент, который используется для сверления, называется «сверлильным сверлом. 5. Одна из кромок сверла, которая называется «перемычкой», не режет металл. VIII. Analyse and translate the following sentences: 1. Different kinds of drills are used in drilling, such as: a single-lipped twist drill, normally less than 1" (inch) in diameter. 2. It is formed of a tubular shank which is twisted of seamless tubing to make a single flute. 3. Coolant is carried through the hollow shank, through a small hole in the drill tip, and chips are washed out through the single flute. 4. A four-lipped hollow core drill is designed to carry chips out through a hollow drill shank. 5. This tool is used for enlarging holes and not for drilling solid metal. A two-lipped hollow type deep drill normally is used in drilling solid metal holes ranging from 1" to 3" in diameter and the tip isattached to a tubular steel shank. 7. Coolant carries chips through the flute into the centre of the drill and then out through the hollow shank. 8. Drills of the same design are also used for holes larger than 3". 9. Theses are j provided with replaceable blades in the tip. IX. Describe Fig. 22 orally using the following words and word combinations: the body of a twist drill, to represent, a cylindrical rod, to have two spiral grooves, to serve, forming, the cutting edges of the drill, to be called lips, the lips, to be connected, a third edge, to be known, a web, to penetrate into material by rubbing, the shank, the drill, clamping the drill in the chuck, to be of different shapes, cylindrical shanks and tapered shanks, the third part of the drill, a drill point, to be ground to a cutting angle, to depend on, material to be drilled 8. THREADING TOOLS There are different types of thread-cutting tools depending upon the operations to be performed. Thread-cutting tools are classified according to the work done into female screw-cutting tools and male screw-cutting tools. According to their construction they are known as; taps, nut taps (Fig. 23), and threading dies. The tap used for cutting female threads in holes is made in the form of a screw provided mostly with straight grooves forming the cutting, edges of the tool. The-tap made of a steel cylindrical bar stock consists of the working part and the shank. The shank serves for fastening the tap in a chuck or in a tap wrench (Fig. 24).  Fig.23. Set of Taps Fig.23. Set of TapsThreads can be cut by means of taps either by means of taps either by hand or on a machine. With manual tapping usually a set of two or three taps is used. The firsts tap serves for cutting threads; then the second tap is used; the third tap is applied for final thread cutting. With mechanical tapping in such materials as cast iron, bronze, brass, copper, aluminium, etc. one tap is used. When steel is tapped sometimes a set of two tools is used. Before cutting threads the tap should be set so that its axis strictly coincides with that of the hole to be cut, otherwise the thread may be oblique. To cut male threads such an instrument as a threading die is used, which is held in the die holder (Fig. 25). A threading die is usually made of internally threaded flat steel stock with  Threading Die Die Holder Fig. 25. cutting grooves or flutes. Between these grooves or flutes there are the cutting edges of the tool by means of which male threading is performed. Exercises. I. Use the following words and phrases in sentences of your own: thread, to classify, female screw-cutting tools, nut tap, to tap, threading die, die holder, tap wrench, male threads, female threads II. Retell the text giving answers to the following questions: 1. What are thread-cutting tools? 2. How are thread-cutting tools classified according to the work done by them? 3. How are thread-cutting tools classified according to their construction? 4. What instrument is used for cutting threads? 5. What is the construction of a tap? 6. How can threads be cut? 7. What is needed for manual tapping? 8. What is the purpose of the first, second and third tap? 9. How should the tap be set before cutting threads and why is it necessary to do that? 10. What instrument is used for cutting male threads? III. Suppy synonyms for the following words: to perform, female thread, male thread, construction, instrument, form IV. Give derivatives from the following words and translate them into Russian: to operate, to perform, to cut, to construct, to thread, to tap, to fasten, usual, to hold V. Supply antonyms for the following words: straight grooves, manual tapping, final, to coincide VI. Translate the following sentences observing different meanings of the word machine: 1. This machine is mainly used for removing large pieces of metal. 2, The engineer explained in his lecture how to machine workpieces of different shapes and sizes. 3. The size and shape of all machine parts should be checked by means of different measuring tools. VII. Make up questions to which the italicized words are the answers: 1. With mechanical tapping in cast iron, bronze, brass, copper, and aluminium one tap is used. 2. When steel is tapped a set of two tools is used. 3. Before cutting threads the tap should be firmly set in a tap wrench. 4. A threading die ismade of internally threaded flat steel stock. VIII. Describe Figs 23 and 24 orally using the following words and word, combinations: the tap, to be made, a cylindrical bar stock, to consist, the working part, the shank, to be used, fastening the threading tool, in a chuck or in a tap wrench, two or three taps, to be applied, manual tapping, the first and the second taps, to serve, to cut threads, the third tap, final thread cutting IX. Giving answers to the following questions describe the threading die shown in Fig. 25: 1. What operations are performed with a threading die? 2. What material is a threading die made of? 3. How is a threading die threaded? 4. What is there between the cutting grooves of a threading die? |