Английский для нефтяников. Практическое занятие 1 Global Giant Практическое занятие 2 Presenting Company

Скачать 1.01 Mb. Скачать 1.01 Mb.

|

|

Задание 5. Соедините глаголы 1-5 с существительными a-e: Task 5. Match the verbs 1-5 with the nouns a-e.

Задание 6. Прочитайте и выучите диалог наизусть: Task 6. Read and learn this dialogue by heart: Supervisor: OK. Listen carefully. Trainee: Understood. Supervisor: First, you turn this hand wheel. Trainee: Clockwise? Supervisor: No, anti-clockwise. Trainee: OK, anti-clockwise. Supervisor: Turn it until it's open. Trainee: OK. Until it's open. Supervisor: Next, close this valve. Trainee: OK. Then close the valve. Supervisor: And then wait a couple of minutes. Trainee: Wait a couple of minutes. Supervisor: Then read the gauge and write the pressure in the log book. Trainee: OK. Got that. Supervisor: And finally, check the flanges and the valves. Trainee: For leaks? Supervisor: Yes, that's right. Задание 7a. Подчеркните ключевые слова, использующиеся для прогноза как в примере: Task 7a. Underline the key phrases used for making forecasts. The first one is done for you:

Задание 7b. Что случилось, если бы прогноз из упражнения 7а сбылся? Закончите предложения: Task 7b. What would happen if these forecasts came true? Complete these sentences:

Практическое занятие 12 Drilling for Oil and Gas Бурение нефтегазовых скважин drill bit буровое долото hole/well скважина drill string бурильная колонна drill collar утяжелённая буровая труба to break up разрывать, фракционировать pump насос pressure давление surface поверхность to contain содержать to reach достигать Задание 1. Прочитайте и переведите текст: Task 1. Read and translate the text: A summary of the drilling process An oil well is created by drilling a hole 5 to 36 inches (127.0 mm to 914.4 mm) in diameter into the earth with a drilling rig, which rotates a drill string with a bit attached. These are the key steps involved in drilling a well:

This process is all facilitated by a drilling rig which contains all necessary equipment to circulate the drilling fluid, hoist and turn the pipe, control down hole pressures, remove cuttings from the drilling fluid and generate onsite power for these operations. The first oil wells were drilled in China in the 4th century or earlier. They reached depths of up to 243 metres and were drilled using bits attached to bamboo poles. The Middle East’s petroleum industry was established by the 8th century, when the street of the newly constructed Baghdad were paved with tar, derived from petroleum that became accessible from natural fields in the region. The first modern oil well was drilled in 1848 by Russian engineer F.N. Semyonov on the Asheron Peninsula north-east of Baku. By 1861, Baku produced about 90% of the world’s oil. The word ‘petroleum’ derives from two Greek words meaning ‘rock oil’. When Edwin Drake struck oil in the first US discovery in 1859, he was actually boring for salt. Until the 1970s, most oil wells were vertical. Using deviated and horizontal drilling it has become possible to reach reservoirs several kilometers away from the drilling place. Задание 2. Заполните таблицу и задайте вопросы с этими словами как в примере: Task 2. Complete the table and ask questions, using these words as in example: Example: How long is the pipeline? What is the length of the pipeline?

Задание 3. Заполните эти вопросы словами из рамки. Начните вопрос со слов 'Whatisthe ...?' или 'How ...?: Task 3. Complete these questions using words from the box. Start each question with 'What is the ...?' or 'How ...?:

A: There are several wells on this rig. The deepest is around 4,500 metres.

A: It can be as much as 15,000 psi, which is why we have a BOP to prevent blowouts.

A: It is approximately 40 metres from the crown block to the working floor.

A: It can withstand wind speeds of anything up to 125 miles per hour.

A: The hole gets narrower as you go down, but at the surface it is more or less 50 cm.

A: These pipes are made of steel with a thickness of just under 1 cm.

A: Each joint is roughly 10 metres in length. If they are all the same, it makes storage much easier.

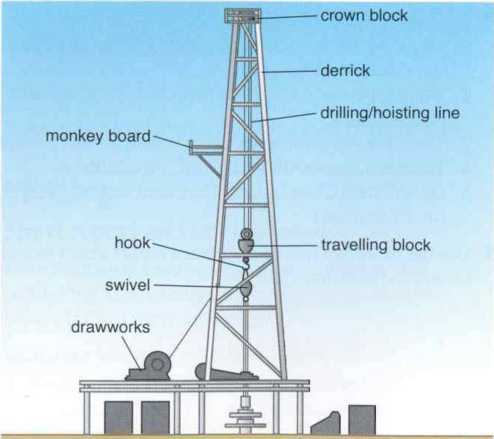

A: They are extremely expensive, ranging from $12,000 to $15,000 each. Задание 4. Изучите диаграмму буровой вышки и соедините описание со словами в диаграмме: Task 4. Study the diagram of a drilling rig and match the descriptions to the words in the diagram:  Example: This raises and lowers drilling equipment in and out of the well, hoisting line.

Задание 5. Прочитайте и переведите текст: Task 5. Read and translate the text: The drill string The work of drilling under the ground is performed by the drill string. The drill string consists of the kelly, sections of drill pipe, the drill collar, and a bit to drill the rock. The kelly is a strong pipe that is always at the top of the drill string. It has four or six sides and goes through the rotary table which turns around (rotates). The rotary table is on the drill floor. There are many lengths of drill pipe between the kelly and the drill collar. Oil workers add sections of drill pipe one by one to the kelly. Each time they add a section, they lift the kelly out of the hole. Then they add a section of ll pipe at the top of the string and lower it back into the ground. At the bottom of the string we can find the drill collar. The bit goes into the collar. Bits are usually tricone – in other words, they have three rotating cones. A circular bit with a hole in the middle is used to take core samples. Drill bits can be covered with industrial diamonds to make them last longer. Drilling mud is pumped through jets in the bit - this lubricates and cools it and, as the mud is circulated, it also carries the pieces of drilled rock fragments to the surface. Задание 6. Закончите предложения: Task 6. Complete these sentences:

Задание 7. Соедините вид работы с его описанием : Task 7. Match the jobs with the descriptions:

Практическое занятие 13 Rotating Systems Вращающиеся системы bottom hole забой drill bit буровая коронка, головка бура drill collar удлинитель, воротник бура tubular цилиндрический, полый sub переводник, переходная муфта logging каротаж drillpipe бурильная труба drillstring бурильная колонна extend удлинять deviate отводить, отклонять joint трубка, замок cone конус, колокол, коническая насадка wear out изнашивание screw завинчивать, привинтить rotate бурить, вращать Task 1. Read and translate the text: Задание 1. Прочитайте и переведите текст: Rotating Systems The bottom hole assembly (BHA) is made up of a drill bit which is used to break up the rock formations, drill collars (which are heavy, thick-walled tubulars used to apply weight to the drill bit) and subs (smaller sections of pipe), such as stabilizers, which keep the drilling assembly centred in the hole. The BHA may also contain other components, such as a down hole motor, Rotary Steerable System, measurement while drilling (MWD) and logging while drilling (LWD) tools. Heavyweight drill pipe (HWDP) is used to make the transition between the drill collars and drill pipe. The function of the HWDP is to provide a flexible transition between the drill collars and the drill pipe. This helps to reduce the number of fatigue failures seen directly above the BHA. A secondary use of HWDP is to add additional weight to the drill bit. Drill pipe makes up the majority of a drill string. A drill string is typically about 15,000 feet in length for an oil or gas well vertically drilled onshore in the United States, and may extend to over 30,000 feet for an offshore deviated well. The components of the string are joined together with special threaded connections known as tool joints, on the ends of each joint. Drill tubulars are manufactured in 31-foot lengths, although they can also be manufactured in 45-foot lengths. Each 31-foot component is referred to as a joint. Typically, two, three or four joints are joined together to make a stand. Pulling the drill string out of or running the drill string into the hole is referred to as tripping. Drill pipe, HWDP and collars are typically tripped in stands to save time. This is a device used for safe automated handling of double or triple stands. There is a typical tricone drilling bit. In today's modern industry, the two main types of drill bits are classed as PDC (Polycrystalline Diamond Compact) and Roller Cone; although the tricone dominates, bicone and mono cone bits do exist. Natural and synthetic diamonds are used in coring bits, as well as for very hard rock drilling with mud motors and turbines. Task 2.Identify the following items of equipment mentioned in reading task 1: Задание 2. Определите, к какому оборудованию из текста для чтения 1 относятся следующие детали: 1. Threaded connections used for joining together the different parts of the string. 2. An outer layer of piping thick enough to withstand the pressure of the sea, down circulation fluids can be passed. 3. A steel and concrete shoring used in a formation to protect the walls of the well. 4. The part of the bottomhole assembly used to break up rock. 5. Heavy pieces of piping which add extra weight to the bottomhole assembly. 6. Devices that enable the drillers to keep the drillstring centred in the hole. 7. The combination of all the elements used downhole in the drilling process. 8. A length of pipe, typically 31 feet long. 9. A combination of pipes and other components, connected to the string above the rig f as the string is extended. 10. A bit with three rotating parts for cutting and breaking the rock. 11. Another name for drillpipe, so-called because it is shaped like a tube. 12. These are smaller sections run between and below drill collars with various functions in the drilling process. Task 3. Use the verbs given in the box below to complete the information about drilling bits. Use the 's' ending if you think it is necessary: Задание 3. Вставьте слова, данные в рамочке, в предложения. Используйте окончание –s там, где необходимо:

1. The bit _____ into the bit sub on the bottom of the drillstring. 2. Drilling mud _____ through channels in the bit. 3. In a rotary cone bit, the cones _____ on sealed and self-lubricating bearings. 4. The teeth or buttons on the bit _____ the rock at the bottom of the well. 5. A PDC bit is the most expensive type, but it _____ more footage in a well then any other type. 6. A bit _____ at a rate of up to 200 rpm. 7. The bit ______ cuttings which are washed back up to the surface by the drilling. 8. A tricone bit _____ and needs to be replaced after 8 to 200 hours of drilling. 9. When a bit has worn out, rate of penetration _____ and the drillpipe _____ a different noise on the drilling floor. Task 4. Read and translate the text. Ask your own questions: Задание 4. Прочитайте и переведите текст. Задайте несколько вопросов по теме: How does the drillstring rotate? Thanks a lot Dieter, that's a good question. First of all, I will explain the traditional rotating system and then we can look at some of the latest technological developments. As you know, there is a hook attached to the hoisting line below the travelling block. Well, attached to the hook is a swivel, which in turn connects to the drillstring. Below that is a heavy four or six-sided pipe called the kelly, which is gripped by something known as the kelly bushing, which in turn fits into the master bushing of the rotary table. The kelly is connected to the drillstring, and so when the rig is powered up, all the components rotate together as a unit. Is that clear? Good ... now let's look at some of the recent developments in power systems… |