Английский язык для направления гороное дело. Облова И. Учебное пособие СанктПетербург 2020 удк 811. 111 (075. 8) Ббк 81. 2Англ я73 О18

Скачать 373.36 Kb. Скачать 373.36 Kb.

|

Text 5 Continuous system for mining ultra-thin seams1. Discuss What system can be called continuous one? 2. Learn to pronounce the words given below.

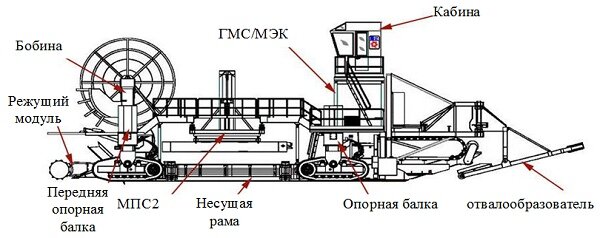

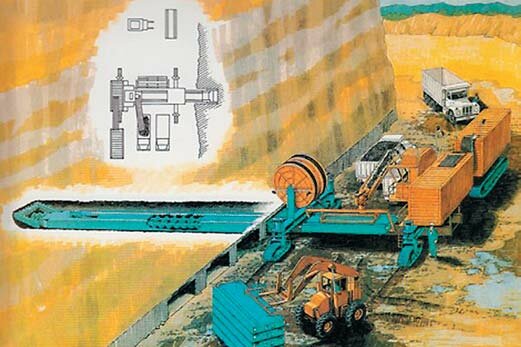

3. Read the text and choose the sentences that best summarise its main idea. Continuous system for mining ultra-thin seams A six-unit Fairchild Haul-Mark continuous haulage system was introduced to one of the highest production longwall producers in South Africa. Specifically for longwall development, this system was introduced in South Africa, continuous haulage can be successful for rapid development in longwall mining. Fairchild International has manufactured more than 800 complete continuous mining systems that operate successfully in a wide variety of conditions worldwide. Fairchild’s new generation continuous mining systems include the F330 and the F410 miners. The Fairchild F410 continuous miner is a full-face, center-place machine, measuring 2,4 metres wide, with the capability of extracting the entire coal seam without repositioning. The machine can extract a coalface width from 4,26 m to 7,54 m from a single-entry position. The machine’s ability to maintain its position in the center of the face while extracting a wide entry width provides more protection, better ventilation, and improved roof conditions. Soft mine bottom is not disturbed since the 38 t machine has its weight equally distributed to provide ground pressure of only 15,398 Pa. Equal weight distribution allows the machine to perform in extreme soft-bottom conditions without disturbing the seam’s underlying strata. The F410 and Haul-Mark continuous systems are currently operating in the US, the United Kingdom and South Africa, in seams as low as 0,85 m and as high as 1,6 m. In addition, the miner can work extremely hard seams due to its shearer cutting principle, which exerts constant pressure in the cutting process. To match the articulation flexibility of the miner, the Haul-Mark haulage system was engineered with multiple points of articulation to follow the miner through entries and break-throughs in multiple-entry mining. Each conveyor component (mobile advance conveyor) articulates 180 degrees from centre point. The conveyor’s articulation with crawler-mounted components can follow any move with the miner. Its overall width – 1,7 m at the crawlers – and its ability to rotate the crawler-propelled receiving section a total of 180 degrees allow parallel movement in the entry, as well as driving 90-degree breakthroughs. An additional advantage is that the Haul-Mark uses the same planetary-gear drives as the F410 miner, thus minimizing spares inventory. The miner’s cutting principle provides a much larger coal-size consistency, with less fine sizes, since the seam is not ground into dust by a ripper-type head. Reports from many thin-seam mines show that the size consistency typically does not exceed 10 % fine sizes depending on the application. The shearing cutting principle also allows the machine operator to raise or lower independently either of the dual cutting shearers to follow the exact seam height, thus producing less ash in the ultimate product. Other designs of Fairchild continuous miners include: – Ability to separate the product right at the coal face by selective mining. A process that cuts and loads the low-ash coal on the first swing. Then the miner cuts and loads rock, high-ash coal or high sulphur coal on the second swing without the costly delays of resetting the miner. – The proven ability to be highly productive by mining a cleaner product from one to three percent above the in-seam ash of the coal seam. Write an abstract of this text. Correct the following sentences about some continuous systems for mining ultra-thin seams. Find the part of the text that gives the correct information. a. The miner’s cutting principle provides a much finer coal-size consistency, with less fine sizes, since the seam is not ground into dust by a ripper-type head. b. The conveyor’s articulation with crawler-mounted components cannot follow any move with the miner. c. The Fairchild F410 continuous miner is a full-face, center-place machine, measuring 4 metres wide, with the capability of extracting the entire coal seam without repositioning. 6. Read the Russian article and render it in English using the following plan. Plan 1. The headline of the article is ... (The article is headlined ...; The headline of the article I've read is...) 2. The author of the article is... 3. The article is taken from ... 4. The central idea of the article is about... (The main idea of the article is... the article is devoted to... the article deals with... the article touches upon... the purpose of the article is to give the reader some information on... the aim of the article is to provide a reader with some material on...). Комплекс Глубокой Разработки Пластов (КГРП) – это гибридная система, использующая подземную технологию с открытой поверхности угольного разреза или специальной разрезной траншеи. Эта система способна добывать запасы угля по более выгодной себестоимости и в более сжатые сроки, чем при традиционном способе добычи.  В1977 г. началось создание комплексов прибортовой добычи угля нового технологического уровня, в развитие технологии шнекобуровой выемки с использованием подземных проходческих комбайнов и разработкой различных схем транспортировки угля на поверхность, обеспечивающих более высокие технико-экономические показатели, чем достигались шнекобуровыми машинами. Наиболее известным комплексом, представленным в то время, стал комплекс The Тhin Seam Miner (разработчик тонких пластов РТП) голландской фирмы «Dieseko», появившийся в 1979 г. Комплекс был разработан группой инженеров из Южной Африки, Европы, США, изготовлен в Голландии судостроительным концерном «Dieseko» и отправлен для сборки в США (рис. 1).  Рис. 1 Схема работы комплекса The Тhin Seam Miner, компании «Dieseko». Комплекс The Тhin Seam Miner был разработан на основе концепции «бурение-извлечение». Комплекс состоял из следующих компонентов: основной рамы, базового каркаса системы, на котором был смонтирован энергетический модуль с дизельным приводом, кабины оператора, двух барабанов с кабелями для подачи электроэнергии к двигателям режущего модуля. На основной раме установлены: механизм балки-толкателя с двумя мощными гидроцилиндрами (длиной по 6,1 м каждый) для подачи режущего модуля на угольный забой и извлечения его в исходное положение, вращатель шнекового конвейера, загрузочный стол шнекового конвейера. Шнековый конвейер состоял из коробчатых секций длиной по 6,1 м. Внутри короба каждой секции размещены два противоположно вращающихся шнека, транспортирующих уголь от режущего модуля к разгрузочному узлу комплекса. Text 6 Joy Manufacturing Company (Africa) (Pty) Limited1. Discuss What industry’s needs does any company have to meet? 2. Learn to pronounce the words given below. Use them in the sentences of your own. height; predominant; requirements; availability; satisfy; substantially 3. Read the text and choose the sentences that best summarise its main idea Joy Manufacturing Company (Africa) (Pty) Limited The current Joy range of continuous miners comprises the 12 HM 31s and 12 HM 21s which, with masses of up to 110 tonnes and cutting heights of up to six metres, are particularly suitable to the unusually high seams predominant in the South African coal mines. The innovative and flexible approach which Joy brings to the market is Dosco (UK) with Twin Boom Miner. This approach led to the marriage of Dosco experience of roadheader mining with Joy technology developed from extensive high seam experience in South Africa. The specific aim of this machine is to deal with hard cutting conditions caused by difficult coal seams with stone bands, inclusions and lenses. In its continual effort to improve its range of products for the SA industry, Joy has added the 10 SC 32 – 56 B to its shuttle car range. The excellent results obtained from the model imported from the USA have encouraged Joy to manufacture a local version. The aim is to integrate the features of the existing 10 SC 22 range with the new technology of the imported model to achieve optimum suitability for the South African coal mining requirements. A prime goal for Joy South Africa is to achieve global standardization of systems and components for all its equipment. Meeting the local requirements and using international components, Joy’s machines can satisfy the requirements of world markets and still supply the South African coal mining industry. Global standardization of systems and components results in better availability of parts and reduces inventories. The end result is a lower cost per tonne for the mine. The Joy 12 HM 21 continuous miner is a unique machine. With a mass of 100 tonnes, it is larger than any other continuous miner in the international Joy and is able to cut coal seams of up to six metres. The 12 HM 31 continuous miner, with a mass of approximately 95 tonnes, is also specifically designed for high seam cutting and is capable of maximum cutting heights of between 3,9 m and 4,5 m. Both these continuous miners, through a combination of main frame construction and high mass, display exceptional stability and are characterized by a substantially enhanced coal cutting and loading capability. They meet the coal mining industry’s need for a hard-cutting machine with less vibration and, longer machine and component life which leads to a lower cost per tonne mined. The 56 D model shuttle car, produced by Joy South Africa, is also a unique machine within the international Joy range in that it has a rated capacity of just over 22 tonnes of coal. It is specifically designed for high productivity in high seams. 4. Answer the following questions. Where is this company located? What machines does it produce? What seams can these machines operate in? What new flexible machine was developed by Joy in cooperation with Dosco? What seams can this road header work in? What is the aim of this machine? What is a prime goal for Joy South Africa? What does global standardization of systems and components result in? What are the specifications of the Joy 12 HM 21 continuous miner? What are the specifications of the 12 HM 31 continuous miner? What do both these continuous miners display? What are the specifications of the 560 D shuttle car? 5. Present the text as a diagrammatic display or as a table or graph and retell it using linkers given below either to add a new idea or to contrast / oppose it.

6. Role play: At the international conference “Coal winning equipment”. Roles 1. The chairman of the conference who introduces the participants and opens and closes the conference. 2. Representatives of different companies speaking of the specifications of their coal mining equipment. 3. The rest of the students are listeners who ask questions and select the coal winning system best suitable for their mine proving their choice. Text 7 Coal mining in English speaking countries1. Discuss What countries are most dependent on coal for energy? 2. Learn to pronounce the words given below. Use them in the sentences of your own. colliery; techniques; surface mining; permanent; predetermining; explosion 3. Read the text. Which paragraph is about: a. The oldest colliery in the world b. First coal cutting machines c. Picks and shovels d. Permanent convict settlements e. The largest coal port in the world f. Political activity of the miners g. Danger at the deep mines Coal mining in English speaking countries UK. The oldest continuously worked mine in the UK and possibly the world is Tower Colliery at the northern end of the South Wales valleys in the heart of the South Wales coalfield. This colliery was started in 1805 and at the end of the 20th century it was bought out by its miners rather than being allowed to be closed. Tower Colliery was finally closed in January 2008. Britain certainly developed the main techniques of underground coal mining. America. Coal mining was evident in colonial America in the early 1700s and the first commercial coal mines in the United States were started around 1730 in Midlothian, Virginia and near Richmond. In the 1880s, coal-cutting machines became available, prior to that, coal was mined underground by hand using a pick and shovel. By 1912, surface mining was underway with steam shovels specifically designed for coal mining. Australia. In 1984 Australia surpassed the US as the world’s largest coal exporter. 1 / 3 of Australia's coal exports were shipped from the Hunter River region of New South Wales, where coal mining and transport had begun nearly two centuries earlier. Coal was found there in 1795. In 1804 the Sydney-based administrations established a permanent convict settlement near the mouth of the Hunter River to mine and load the coal, predetermining the town’s future as a coal port by naming it Newcastle. Today Newcastle is the largest coal port in the world. Canada. Canada had a small coal industry concentrated at Cape Breton in Nova Scotia. At its peak in 1949 25K miners dug 17 million metric tons of coal from mines. The miners lived in company towns and were politically active. Westray Mine closed in 1992 after an explosion killed 26 miners. All the mines were closed by 2001. Now Canada chiefly imports energy from the U.S. 4. Look through the texts given above and complete the chart.

5. Find in the text phrases, which mean the following: a. непрерывно работающая подземная шахта b. быть выкупленным c. технология подземной разработки d. дальнейший прогресс e. шахта промышленного значения f. врубовая машина g. обогнать (США) по … h. мировой экспортер угля i. одна треть j. предопределять будущее (города) k. быть политически активным l. закрыть шахту 6. Find in the text phrases and translate them into Russian. a. in the heart of the coalfield b. became available c. use a pick and shovel d. specifically designed for e. coal exports were shipped f. name given by g. mouth of the Hunter River h. established a settlement i. by naming it … j. concentrated k. at its peak l. chiefly imported from Text 8 Methods of coal extraction1. Discuss What methods of coal extraction do you know? 2. Learn to pronounce the words given below. Use them in the sentences of your own. extraction; geologic; depth, burial, surface; techniques; quality; thickness 3. Using a dictionary find out the meaning of the following words. seam, bed, stratum, layer, formation What is common in meaning for all these words? 4. Read the text and choose the sentences that best summarise its main idea. Methods of coal extraction The most economical method of coal extraction from coal seams depends on the depth and quality of the seams, and the geology and environmental factors of the area. Coal mining processes are generally differentiated by whether they operate on the surface or underground. Many coals extracted from both surface and underground mines require washing in a coal preparation plant. Coal is mined only where technically and economically feasible. Evaluation of technical and economic feasibility of a potential mine requires consideration of many factors: regional geologic conditions; coal seam continuity, thickness, structure, quality, and depth; strength of materials for roof and floor conditions; topography, especially altitude and slope; climate; access; surface drainage patterns; ground water conditions; availability of labor and materials; quality, and destination; and capital investment requirements. There are two basic methods of mining a coal reserve: surface mining and deep underground mining. The choice of mining method depends primarily on depth of burial and thickness of the coal seam. Seams relatively close to the surface, at depths less than approximately 55 m, are usually surface mined. Coals that occur at depths of 90 m are usually deep mined but, in some cases, surface mining techniques can be used. For example, some western U.S. coals that occur at depths of 60 m are mined by open pit methods. Coals occurring below 90 m are usually deep mined. Notes: surface mine / mining – карьер / открытая добыча (разработка) deep underground mine / mining – шахта / подземная добыча (разработка) coal preparation plant – обогатительная фабрика feasible ['fi:zəbl] – подходящий, возможный, выполнимый technical and economic feasibility – технико-экономическое обоснование roof – n. кровля floor– n. геол. пласт, залежь, в частности, залежь непосредственно под залежью разрабатываемого ископаемого altitude – n. высота над уровнем моря slope – n. уклон drainage patterns – дренажная система depth of burial – глубина залегания 5. Explain the terms marked in bold. 6. Based on the text hereinabove give a brief explanation to the following concepts. technical and economic feasibility; geological and topography conditions; two basic methods of coal reserve mining. Text 9 Modern surface and underground mining1. Discuss What ranks of coal do you know? Give at least four terms. 2. Learn to pronounce the words given below. Use them in the sentences of your own. anthracite; subsequent; terrain; equipment; hydraulic; thermal; metallurgical 3. Read the text and choose the sentences that best summarise its main idea. Modern surface and underground mining When coal seams are near the surface, it may be economical to extract the coal using open cut mining methods. Open cast coal mining recovers a greater proportion of the coal deposit than underground methods, as more of the coal seams in the strata may be exploited. Opencast coal mines can cover many square kilometers. Most open cast mines in the United States extract bituminous coal. In Australia open cast mining is used for both thermal and metallurgical coals. In South Wales open casting for steam coal and anthracite is practiced. Surface mining accounts for around 80 % of production in Australia, while in the USA it is used for about 67 % of production. Globally, about 40 % of coal production involves surface mining. The most usual surface mining method for coal is strip or area mining. Strip mining exposes the coal by removing the overburden in long cuts or strips. The spoil from the first strip is deposited in an area outside the planned mining area. Spoil from subsequent cuts is deposited as fill in the previous cut after coal has been removed. Usually, the process is to drill the strip of overburden next to the previously mined strip. The drill holes are filled with explosives and blasted. The overburden is then removed using large earthmoving equipment such as draglines, shovel and trucks, excavator and trucks, or bucket-wheels and conveyors. This overburden is put into the previously mined (and now empty) strip. When all the overburden is removed, the underlying coal seam will be exposed (a “block” of coal). This block of coal may be drilled and blasted, if hard, or otherwise loaded onto trucks or conveyors for transport to the coal preparation plant. Once this strip is empty of coal, the process is repeated with a new strip being created next to it. This method is most suitable for areas with flat terrain. The suitability of equipment is governed by geologic conditions. For example, to remove overburden that is loose or unconsolidated, a bucket-wheel excavator might be most productive. The life of some area mines may be more than 50 years. Most coal seams are too deep underground for opencast mining and require underground mining, this method currently accounts for about 60 % of world coal production. In deep mining, the room and pillar progress along the seam, while roof-supports and timber are left standing to support the mine roof. Once room and pillar mines have been developed to a stopping point (limited by geology, ventilation, or economics), a supplementary version of room and pillar mining, termed second mining or retreat mining, is commonly started. This is when miners remove the coal in the pillars, thereby recovering as much coal from the coal seam as possible. A work area that is involved in pillar extraction is called a pillar section. Modern pillar sections use remote-controlled equipment, including large hydraulic mobile roof-supports, which can prevent collapse until the miners and their equipment have left a work area. The mobile roof supports are similar to a large dining-room table, but with hydraulic jacks for legs. After the large pillars of coal have been mined away, the mobile roof support's legs shorten and it is withdrawn to a safe area. The mine roof typically collapses once the mobile roof supports leave an area. Notes: open cut – open cast, open pit, strip overburden – n. отвал, v. перегружать cut, strip – n. срез, полоса spoil – n. вынутый грунт subsequent – adj. последующий drill – v. прокладывать, пробуривать explosive – n. взрывчатка blast – v. взрывать draglines – n. драглайн, скребковый экскаватор shovel – n. экскаватор одноковшовый bucket-wheels – n. роторный экскаватор coal preparation – coal washing, coal processing flat terrain – плоская местность govern – v. диктовать, обуславливать, определять roof-support – n. опора (кровли), крепеж timber – n. крепежный лес retreat mining – выемка обратным ходом pillar(s) – n. целик remote-controlled equipment – дистанционно управляемое оборудование hydraulic mobile roof-supports – подвижные гидравлические опоры hydraulic jack – гидравлический домкрат 4. Read the statements and say if they are true or false. a. It may be not economical to extract the coal using open cut mining methods when coal seams are near the surface. b. Open cast coal mining recovers a greater proportion of the coal deposit than underground methods. c. Most open cast mines in the United States extract metallurgical coals. d. Globally, coal production involves about 50 % of surface mining. e. Strip mining is the most usual surface mining method for coal extraction. f. They remove overburden using large earthmoving equipment such as draglines, excavator and trucks, or bucket-wheels and conveyors. g. They drillor blast coal for easy transportation to the coal preparation plant. h. Geologic conditions do not govern the choice of equipment. i. The life of open pits could be 50 years or longer. 5. Match the Russian words and word-combinations given below with their English equivalents.

6. Translate the following phases. a. располагаться у поверхности b. извлекать уголь c. занимать / покрывать большую площадь d. практиковать добычу угля e. насчитывать … % f. самый обычный метод – это … g. укладывать вынутый грунт h. пробуривать отверстия i. закладывать взрывчатку j. снимать вскрышную породу k. определять технику под условия l. загружать на машины / конвейеры m. повторять процесс n. транспортировать Text 10. Modern mining1. Discuss What are requirements to a modern engineer? What skills should a mining engineer have to meet the requirements of mining industry? What technological advancements in coal mining do you know? 2. Learn to pronounce the words given below. Use them in the sentences of your own. technological; personnel; require; machine; equipment 3. Read the text and choose the sentences that best summarise its main idea. Modern mining Technological advancements have made coal mining today more productive than it has ever been. To keep up with technology and to extract coal as efficiently as possible modern mining personnel must be highly skilled and well trained in the use of complex, state-of-the-art instruments and equipment. Future coal miners have to be highly educated and many jobs require 4-year college degrees. Computer knowledge has also become greatly valued within the industry as most of the machines and safety monitors are computerized. In the United States, the increase in technology has significantly decreased the mining workforce to 105K miners working in fewer than 2K mines today. Notes: state-of-the-art – adj. современный workforce – n. рабочая сила 4. Find the definition and put the correct letter from a-e into the boxes given below. a. Technological advancements have made coal mining more productive b. To extract coal as efficiently as possible c. Personnel must be highly skilled and well trained d. Computer knowledge has also become greatly valued within the industry e. The increase in technology has significantly decreased the mining workforce      Make up a presentation on one of the coal mining methods. Follow the plan. Plan a. Introduce the group you present (act on behalf …) b. Introduce the issue (problem, task, goal) c. The main part (reason why this method of mining is the best one, including economical study and geological conditions) d. Draw conclusions. 6. Work in groups. Solve the following problem. Coal mining company needs to take a decision on methods of excavation in a certain area. Mining engineers have gathered at the meeting. They split into two teams. Each team proves that their method of coal extraction is better, brining all the advantages and disadvantages. Text 11. Principal underground mining methods 1. Discuss What is the most popular method of coal extraction? What is the safest method? What is the oldest practice? 2. Learn to pronounce the words given below. Use them in the sentences of your own. shearer; hydraulic; roof supports; tungsten; carbide; teeth 3. Read the text below and learn about five modern major underground methods. Principal underground mining methods Longwall mining accounts for about 50 % of underground production. Shearer is a sophisticated machine with a rotating drum that moves mechanically back and forth across a wide coal seam. The loosened coal falls on to a pan-line that takes the coal to the conveyor belt for removal from the work area. Longwall systems have their own hydraulic roof supports, which advance with the machine as mining progresses. As the longwall mining equipment moves forward, overlying rock that is no longer supported by coal is allowed to fall behind the operation in a controlled manner. The supports make possible high levels of production and safety. Sensors detect how much coal remains in the seam while robotic controls enhance efficiency. Longwall systems allow a 60 – to – 100 % coal recovery rate when surrounding geology allows their use. Continuous mining utilizes a machine with a large rotating steel drum equipped with tungsten carbide teeth that scrape coal from the seam. Operating in a “room and pillar” system – where the mine is divided into a series of 20 – to – 30 foot “rooms” or work areas cut into the coal bed it can mine as much as five tons of coal a minute, more than a non-mechanized miner of the 1920s would produce in an entire day. Continuous miners account for about 45 % of underground coal production. Conveyors transport the removed coal from the seam. Remote-controlled continuous miners are used to work in a variety of difficult seams and conditions, and robotic versions controlled by computers are becoming increasingly common. Blast mining is an older practice that uses explosives such as dynamite to break up the coal seam, after which the coal is gathered and loaded on to shuttle cars or conveyors for removal to a central loading area. This process consists of a series of operations that begins with “cutting” the coal bed so it will break easily when blasted with explosives. This type of mining accounts for less than 5 % of total underground production in the U. S. today. Shortwall mining, a method currently accounting for less than 1 % of deep coal production, involves the use of a continuous mining machine with moveable roof supports, similar to longwall. The continuous miner shears coal panels 150 – 200 feet wide and more than a half-mile long, having regard to factors such as geological strata. Retreat mining is a method in which the pillars or coal ribs used to hold up the mine roof are extracted, allowing the mine roof to collapse as you retreat. This is one of the most dangerous forms of mining owing to imperfect predictability of when the ceiling will collapse and possibly crush or trap workers in the mine. Notes: longwall – n. длинный забой/ лава shearer – n. комбайн, выработка drum – n. шнек, цилиндр pan-line – n. став рештаков            continuous mining – метод непрерывной разработки coal rib – столб, целик tungsten – n. вольфрам carbide – n. карбид shortwall mining – n. короткий забой 4. Explain the terms marked in bold. 5. Translate the following phrases: a. насчитывать около ... % b. двигаться вперед и назад c. срезанный уголь падает d. система выработки длинным забоем e. оборудование продвигается вперед f. сенсорные датчики определяют g. использовать машины h. конвейеры транспортируют i. использовать взрывчатые материалы j. метод включает использование k. учитывать факторы l. работать в трудных условиях m. обрушение кровли 6. Work in pairs. Discuss the principal mining methods based on the text above. Use the following phrases: I think that / I believe that / to my mind/ in my opinion This method is very productive / efficient / popular/ expensive / dangerous The method accounts for about The major principle / method is The method uses the following equipment Text 12. DrillingDiscuss What are the challenges of drilling? What challenges are unique to oil drilling in the Arctic? What technological advancements to meet drilling challenges do you know? 2. Learn to pronounce the words given below. rotary – вращательного действия  drilling percussive – ударного действия бурение  production 3. Match the English words and word-combinations given below with their Russian equivalents.

4. Read the text and choose the sentences that best summarise its main idea. Drilling The CMG’s Drilling System Division produces the full range of Boart Longyear rotary percussive hydraulic rockdrills and a range of drilling rigs for the mining and construction markets. A particular feature of the drilling rig range is the ultra-low seam drill rigs for face and roof drilling. These units have been designed to operate in seams as low as 1,5 m in height. The Boart Longyear series of rockdrills can be retrofitted onto most makes of drilling equipment, a process which can be carried out within an eight-hour man shift. The HD series of rockdrills has been successful around the world because of their productivity, reliability and ease of maintenance. This package is the typical combination of benefits that makes Boart Longyear the preferred choice for many people in the mining and construction industries. The latest addition to the popular rockdrill series is the BL HD165, which extends the capability of the current range. 5. Answer the following questions. What type of the drilling system is described in the text? What environment does it work in? How long is drilling process? 6. Work with your partner. Prepare to give a short talk about some drilling systems, their advantages and disadvantages. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

elective mining

elective mining